Blog

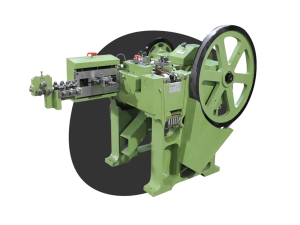

Wire Nail Making Machine

Enhance your production efficiency with Gujarat Wire Products’ wire nail making machines. Choose from standard or high-speed variants, designed for durability, ease of operation, and low maintenance. Invest in reliable equipment to meet your business needs and boost productivity. Order now for superior performance!

Enhance Your Production with Our Advanced Wire Nail Making Machines

Are you looking for high-quality wire nail making machines? Gujarat Wire Products offers the perfect solution. Our advanced machines enhance your production efficiency. Whether you need standard wire nail making machines or high-speed variants, we have you covered.

The Importance of Wire Nail Making Machines

Wire nails are essential in various construction and manufacturing projects. A reliable wire nail making machine ensures a steady supply of nails. Investing in the right machine boosts productivity and reduces operational costs.

Our Range of Wire Nail Making Machines

We offer two main types of wire nail making machines. Each is designed to meet specific production needs and ensure top-notch performance.

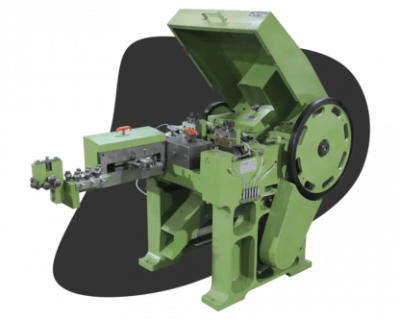

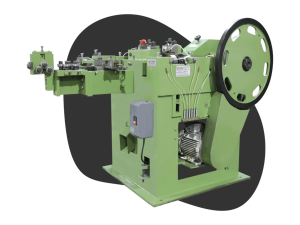

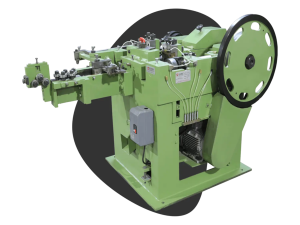

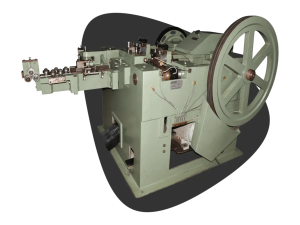

1. Standard Wire Nail Making Machines

Our standard wire nail making machines are perfect for small to medium-scale productions. These machines are user-friendly and easy to maintain. They offer consistent output, ensuring you meet your production targets without hassle. The durability of these machines guarantees long-term use, making them a cost-effective investment.

|  |  |

|  |

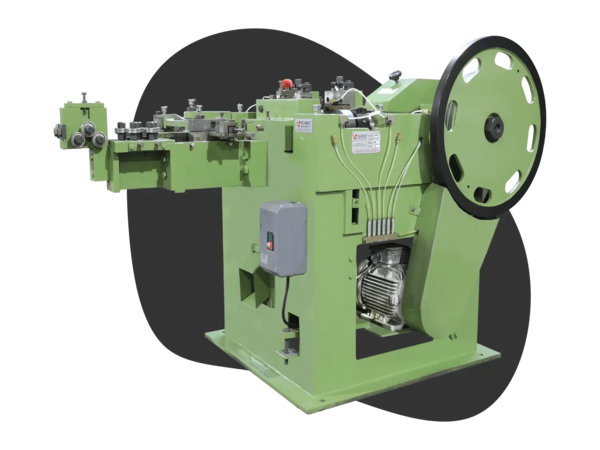

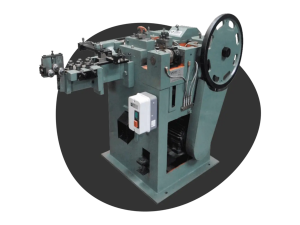

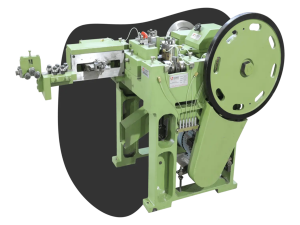

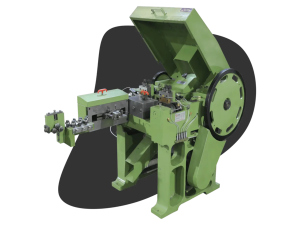

2. High-Speed Wire Nail Making Machines

For large-scale productions, our high-speed wire nail making machines are ideal. These machines operate at high efficiency, producing nails at a faster rate. They are equipped with advanced features to handle heavy-duty operations seamlessly. The high-speed machines reduce production time, enabling you to meet large orders promptly.

|  |  |

Key Features of Our Wire Nail Making Machines

Our wire nail making machines come with several outstanding features:

- High Durability: Built to last, ensuring minimal downtime and long-term use.

- Ease of Operation: User-friendly design makes them easy to operate, even for beginners.

- Consistent Performance: Provides reliable and consistent nail production.

- Low Maintenance: Requires minimal maintenance, saving time and costs.

- Energy Efficient: Designed to consume less power, reducing operational costs.

Why Choose Gujarat Wire Products?

At Gujarat Wire Products, we prioritize quality and customer satisfaction. Our wire nail making machines are crafted using the best materials and technology. We understand the importance of reliable machinery in your production line. Hence, our machines undergo rigorous testing to ensure they meet the highest standards.

Applications of Wire Nails

Wire nails produced by our machines are used in various applications, including:

- Construction: Essential for framing, roofing, and other construction tasks.

- Furniture Manufacturing: Used in assembling furniture pieces.

- Packaging: Helps in securing wooden crates and boxes.

- DIY Projects: Ideal for various do-it-yourself tasks around the home.

Enhancing Your Production Line

Our wire nail making machines are designed to seamlessly integrate into your production line. They enhance efficiency, reduce waste, and ensure a steady supply of high-quality nails. By choosing our machines, you are investing in reliable equipment that supports your business growth.

Final Thoughts

In conclusion, investing in high-quality wire nail making machines from Gujarat Wire Products is a smart decision. Our machines cater to various production needs, offering both standard and high-speed options. With features like durability, ease of operation, and energy efficiency, our machines stand out in the market. Enhance your production capabilities today with our advanced wire nail making machines.

Contact information and how to order

To order SWire Nail Making Machines from Gujarat Wire Products, you can contact us through the following channels:

– Phone: +91-9824456375

– Email: info@gujaratwireproducts.com

– Website: www.gujaratwireproducts.com/contact-us

Read About: Automatic High Speed Wire Nail Making Machine

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.