Blog

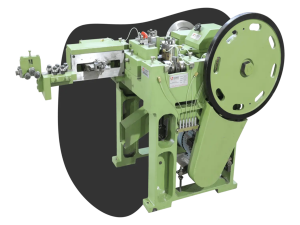

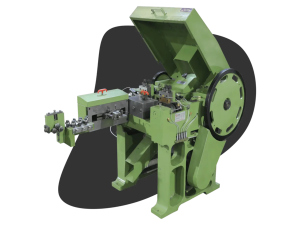

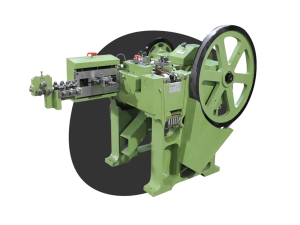

Automatic High Speed Wire Nail Making Machine

Discover Gujarat Wire Products’ Automatic High-Speed Wire Nail Making Machine. Enhance your productivity with models GHN2, GHN3, and GHN4, designed for efficiency and precision. Our machines offer high-speed operation, low maintenance, and user-friendly design, making them the ideal choice for your nail production needs.

Boost Your Productivity with Automatic High-Speed Wire Nail Making Machines

Gujarat Wire Products is a renowned manufacturer of Automatic High-Speed Wire Nail Making Machines. Our machines are engineered for superior performance and durability. Whether you’re in construction, manufacturing, or any industry requiring nails, our machines are the ideal solution.

Why Choose Automatic High-Speed Wire Nail Making Machines?

Automatic High-Speed Wire Nail Making Machines revolutionize nail production. These machines offer unmatched efficiency and precision, significantly reducing manual labour. They ensure consistent quality, helping businesses meet high demand without compromising on standards.

Advantages of Our Wire Nail Making Machines

Our wire nail making machines are designed for high output. They are user-friendly, ensuring smooth operation even for non-experts. Maintenance is minimal, which means more uptime and less hassle for your production line.

Range of Our Machines

We offer three models: GHN2, GHN3, and GHN4. Each model caters to different production needs, providing flexibility and efficiency.

|  |  |

Key Features of Our Machines

High-Speed Operation

- Our machines operate at high speeds, significantly increasing production rates. This allows businesses to meet high demand efficiently.

Precision Engineering

- Each machine is engineered for precision. This ensures that every nail produced meets exact specifications, reducing waste and improving quality.

Durability and Reliability

- Built with high-quality materials, our machines are durable and reliable. They are designed to withstand the rigors of continuous operation, ensuring long-term performance.

User-Friendly Design

- The intuitive design makes our machines easy to operate. Minimal training is required, allowing operators to quickly adapt and maintain high productivity.

Low Maintenance

- Our machines require minimal maintenance, reducing downtime and operational costs. This ensures that your production line runs smoothly and efficiently.

Applications of Wire Nail Making Machines

Our wire nail making machines are versatile, catering to various industries. They are essential for construction, manufacturing, and carpentry, among others. Businesses can produce nails of different sizes and types, meeting diverse market needs.

Enhancing Efficiency and Productivity

Investing in our Automatic High-Speed Wire Nail Making Machines means enhancing your business’s efficiency and productivity. These machines reduce manual labor, increase output, and ensure consistent quality. They are a valuable addition to any production line.

Why Gujarat Wire Products?

Gujarat Wire Products is a trusted name in the industry. We are committed to providing top-quality machines that meet the highest standards. Our focus is on delivering reliable, efficient, and cost-effective solutions for our customers.

Expertise and Experience

- With years of experience, we have the expertise to design and manufacture superior wire nail making machines. Our team is dedicated to continuous improvement and innovation.

Customer-Centric Approach

- We prioritize our customers’ needs, offering customized solutions to meet specific requirements. Our support team is always ready to assist, ensuring a seamless experience.

Quality Assurance

- Every machine undergoes rigorous testing to ensure it meets our quality standards. We use the best materials and latest technology to deliver machines that perform exceptionally.

Competitive Pricing

- We offer competitive pricing without compromising on quality. Our machines provide excellent value for money, making them a smart investment for your business.

Conclusion

Automatic High-Speed Wire Nail Making Machines from Gujarat Wire Products are the perfect solution for businesses looking to boost productivity and efficiency. With our range of models, high-quality construction, and exceptional performance, you can meet the demands of your industry with confidence.

Contact information and how to order

To order Automatic High Speed Wire Nail Making Machines from Gujarat Wire Products, you can contact us through the following channels:

– Phone: +91-9824456375

– Email: info@gujaratwireproducts.com

– Website: www.gujaratwireproducts.com/contact-us

Read About: Panel Pin Making Machine

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.