Blog

Panel Pin Making Machine

Looking to boost your manufacturing efficiency? Gujarat Wire Products offers advanced Panel Pin Making Machines. Choose from our High-Speed and Wire Nail Making Machines, designed for precision and speed. Upgrade your production line today and ensure top-quality outputs with minimal effort. Visit us to learn more!

The Evolution of Precision: Panel Pin Making Machines at Gujarat Wire Products

In the world of manufacturing, precision and efficiency drive success. We stand at the forefront, offering innovative solutions with our Panel Pin Making Machines range. These machines are designed to enhance production lines with their high-speed operations and reliability.

Types of Panel Pin Making Machines

Gujarat Wire Products specializes in two types of Panel Pin Making Machines: the High-Speed Nail Making Machine and the Wire Nail Making Machine. Each machine caters to different production needs, providing a variety of options for manufacturers.

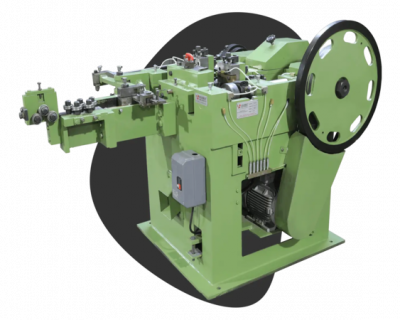

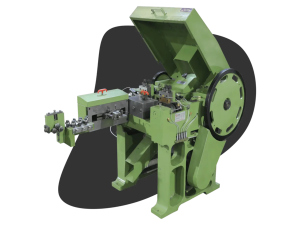

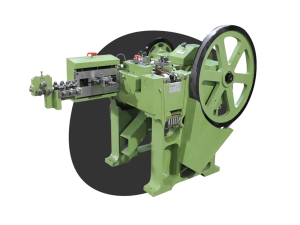

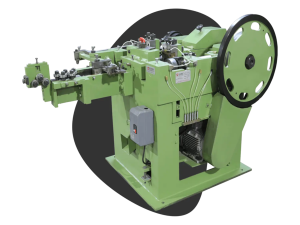

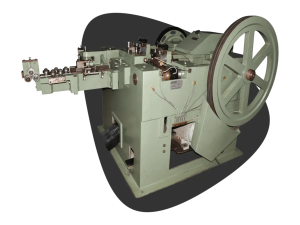

High-Speed Nail Making Machine

The High-Speed Nail Making Machine is engineered for performance. It significantly reduces the nail-making time, which boosts overall productivity. This machine is ideal for businesses aiming to increase output without compromising on the quality of the nails produced.

|  |  |

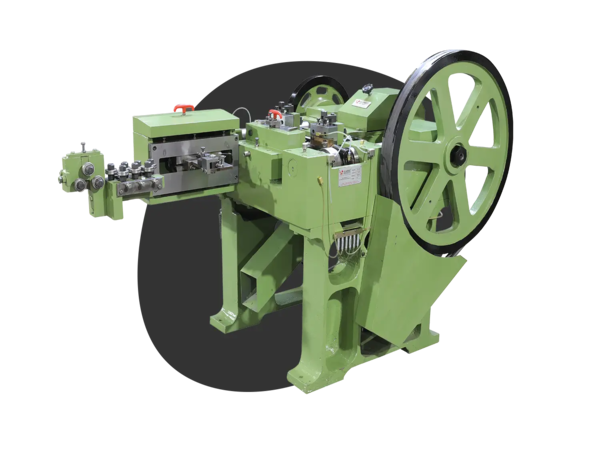

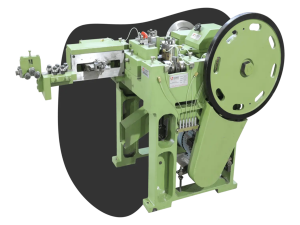

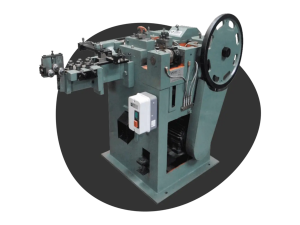

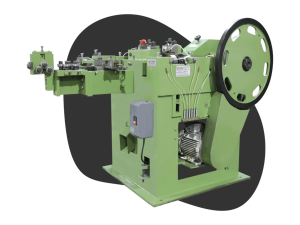

Wire Nail Making Machine

For those requiring versatility, the Wire Nail Making Machine is a perfect choice. It is equipped to handle a wide range of nail sizes, making it suitable for various applications from simple household tasks to more complex construction projects. Its robust design ensures longevity and minimal maintenance.

|  |  |

|  |

Features of Panel Pin Making Machines

Both types of machines boast features that make them stand out in the market:

- Precision Engineering: Ensures that each nail is crafted with the highest accuracy.

- User-Friendly Interface: Simplifies the operation process, making it accessible to all levels of machine operators.

- Energy Efficiency: Reduces power consumption, leading to cost savings and a reduced environmental footprint.

- Durability: Constructed from high-quality materials, these machines are built to last.

Benefits of Using Gujarat Wire Products’ Machines

Choosing Gujarat Wire Products’ machines brings several benefits:

- Increased Production Speed: Machines operate at high speeds, increasing your production capacity.

- High-Quality Outputs: Each nail is consistently made to meet rigorous standards.

- Cost-Effectiveness: Efficient production and low maintenance costs lead to better profitability.

Industries Benefiting from Panel Pin Making Machines

Various industries can benefit from these machines, including:

- Construction: For fast and reliable nail production.

- Furniture Making: Ensures the availability of high-quality nails for furniture assembly.

- Automotive: For manufacturing small, precise pins used in automotive parts.

Conclusion: Why Choose Gujarat Wire Products?

Gujarat Wire Products is not just a manufacturer; we are pioneers in the nail-making industry. With their advanced Panel Pin Making Machines, they offer solutions that propel your business towards greater efficiency and success.

Ready to enhance your production capabilities? Contact Us to discover more about our Panel Pin Making Machines and how they can transform your manufacturing process.

Contact information and how to order

To order Panel Pin Making Machines from Gujarat Wire Products, you can contact us through the following channels:

– Phone: +91-9824456375

– Email: info@gujaratwireproducts.com

– Website: www.gujaratwireproducts.com/contact-us

Read About: Spiral Nail Making Machine

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.