Blog

Spiral Nail Making Machine

Discover top-quality Spiral Nail Making Machines at Gujarat Wire Products. Choose between High-Speed Wire Nail Machines for high productivity and Wire Nail Machines for versatility. Enhance your production with our advanced, reliable, and efficient machines.

Discover the Best Spiral Nail Making Machines Today

At Gujarat Wire Products, we specialize in manufacturing top-quality Spiral Nail Making Machines. Our machines are known for their efficiency and reliability. With our advanced technology, you can be assured of superior performance and excellent results.

Types of Spiral Nail Making Machines

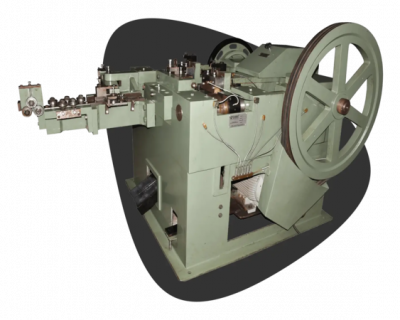

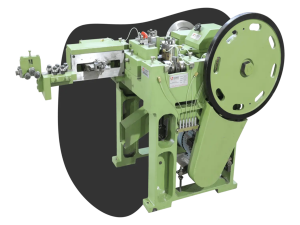

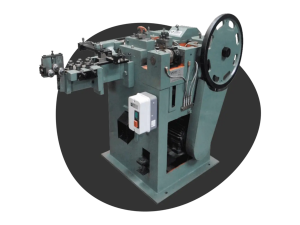

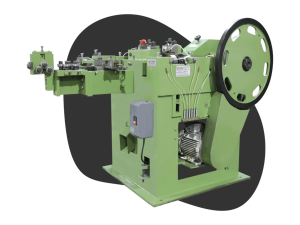

High-Speed Wire Nail Making Machines

High-Speed Wire Nail Machines are designed for maximum efficiency. They produce nails at a fast rate, ensuring high productivity. These machines are perfect for large-scale production needs. Their advanced design ensures consistent quality and reduced waste.

|  |  |

Benefits of High-Speed Wire Nail Making Machines

- High Productivity: These machines can produce a large number of nails quickly.

- Consistent Quality: Each nail produced meets strict quality standards.

- Reduced Waste: Advanced technology minimizes material wastage.

- Durability: Built with robust materials, these machines offer long-lasting performance.

Applications of High-Speed Wire Nail Making Machines

High-Speed Wire Nail Machines are suitable for various industries. They are widely used in construction, furniture making, and packaging. Their ability to produce nails quickly and efficiently makes them a valuable asset.

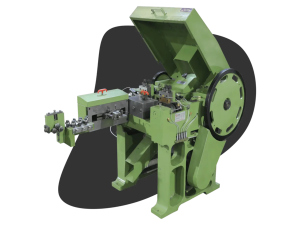

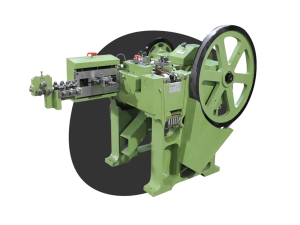

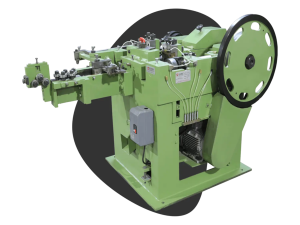

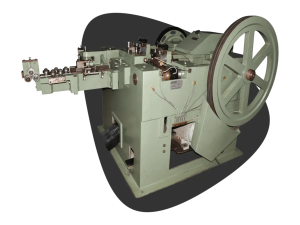

Wire Nail Making Machines

Wire Nail Machines are versatile and reliable. They are designed to handle different nail sizes and types. These machines offer a perfect balance between speed and precision.

|  |  |

|  |

Benefits of Wire Nail Making Machines

- Versatility: Suitable for producing different types of nails.

- Precision: Ensures accurate nail dimensions and shapes.

- Efficiency: Optimized for consistent performance and minimal downtime.

- Cost-Effective: Provides great value for the investment.

Applications of Wire Nail Making Machines

Wire Nail Machines are used across various sectors. They are ideal for small to medium-scale nail production. Industries like carpentry, general manufacturing, and repair services benefit from their flexibility.

Why Choose Gujarat Wire Products?

Choosing Gujarat Wire Products means opting for quality and reliability. Our Spiral Nail Making Machines are crafted with precision engineering. We focus on delivering machines that enhance your production capabilities.

- Our Commitment to Quality: We are committed to providing the best quality machines. Each machine undergoes rigorous testing to ensure top performance. Our quality assurance process guarantees that you receive a reliable product.

- Innovation and Technology: At Gujarat Wire Products, we embrace innovation. Our machines are equipped with the latest technology. This ensures high efficiency and cutting-edge performance.

- Customer Support: We believe in supporting our customers throughout their journey. Our dedicated customer support team is always ready to assist. From installation to maintenance, we provide comprehensive support.

How to Choose the Right Spiral Nail Making Machine

Selecting the right machine depends on your specific needs. Consider the following factors:

- Production Volume: Determine the quantity of nails you need to produce.

- Nail Types: Identify the types of nails required for your applications.

- Budget: Consider the investment you are willing to make.

- Space: Ensure you have adequate space for the machine.

Our team can help you choose the perfect machine. We offer expert advice to match your production requirements.

Conclusion

Gujarat Wire Products offers the best Spiral Nail Making Machines in the market. Our High-Speed Wire Nail Machines and Wire Nail Machines cater to diverse needs. With our commitment to quality and innovation, you can achieve superior production efficiency.

Contact information and how to order

To order Kata Tar Machines from Gujarat Wire Products, you can contact us through the following channels:

– Phone: +91-9824456375

– Email: info@gujaratwireproducts.com

– Website: www.gujaratwireproducts.com/contact-us

Read About: Coil Nail Machine

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.