Blog

Wire Nail Making Machine

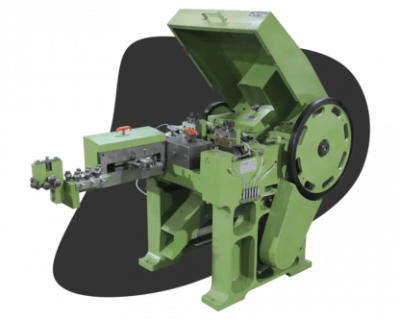

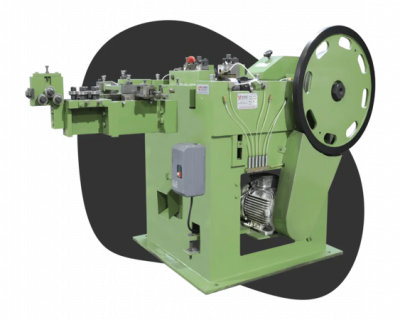

Wire Nail Making Machine

In a continuous nail manufacturing process, galvanized wire is fed into a machine mold, cut using a nail cutter, and then shaped into a nail head by a hammer. The finished nail then drops on its own. We can produce any type of nail by using a wire nail machine.

Types, Sizes, and Functions of Wire Nail Making Machine

Wire nail-making machines comprise various types of machines that specialize in distinct features and functions. Every nail machine has different capabilities for producing nails, as well as its own variety of quality parameters and production capabilities. A nail machine can produce wire nails from any metal, such as brass, copper, steel, and others.

The production of nails is made efficient and affordable by nail-producing machines. These machines are capable of producing a wide variety of nails, including those with round heads, pop heads, flat heads, countersunk heads, and lost heads. For the best accuracy in nail manufacture, nail-making machines typically include auxiliary parts.

Before you start using a wire nail machine, you need to conduct a quality test on the machine. High-speed wire nail machines fall into the category of fully computerized machines with advanced technology.

The Feature Required in Wire Nail Making Machine

Some nail-making machines require features for quality products in large quantities. Here we mention below a few essential features.

- Reliable

- Law maintenance

- High speed

- Easy to use

- High production capacity

Wire Nail Making Machines All Over The World

Many manufacturers are investing in the development of manufacturing capacity as the demand for wire nails rises. Professional carpenters recognize wire nails as a useful tool for a range of operations, including sanding, carving, and shaping. Additionally, the rising demand for construction wire nails is expected to encourage local manufacturers to invest in nail plants.

Read More: Types Of Wire Nails

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.