Blog

Concrete Nail Machine

Looking to enhance your manufacturing efficiency? Gujarat Wire Products offers top-notch Concrete Nail Machines, including High-Speed and Wire Nail Making Machines. Ideal for diverse industrial applications, these machines ensure robust performance and superior output. Explore our products and revolutionize your production line today!

Revolutionize Your Production with Advanced Concrete Nail Machines

In the bustling world of construction and manufacturing, efficiency is key. Concrete nail machines have become essential tools, boosting productivity with remarkable precision. At Gujarat Wire Products, we specialize in crafting machines that not only meet but exceed industry standards.

Why Choose Concrete Nail Machines?

Concrete nails are integral in various construction projects, from building frameworks to installing drywalls. Traditional methods of nail production are time-consuming and labor-intensive. Our concrete nail machines revolutionize this process by automating and speeding up production, ensuring you stay ahead in the competitive market.

Types of Concrete Nail Machines We Offer

At Gujarat Wire Products, we proudly present two distinct types of concrete nail machines:

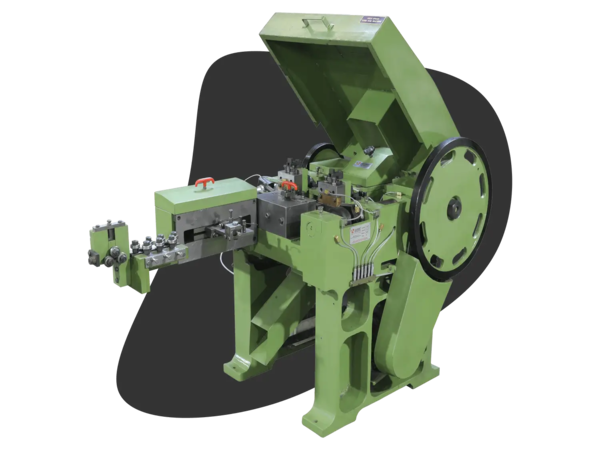

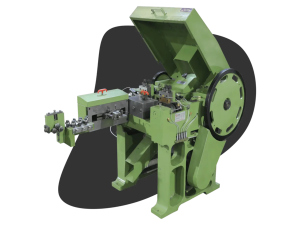

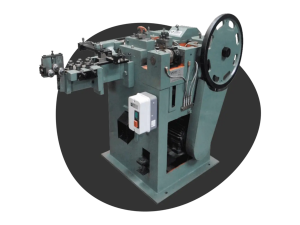

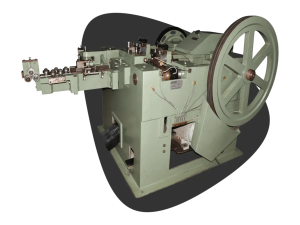

High-Speed Nail Making Machine

This powerhouse maximizes output without compromising on quality. It’s designed for businesses that require a high volume of nails, delivering consistent results swiftly. With this machine, you can expect a significant boost in your production line’s efficiency.

|  |  |

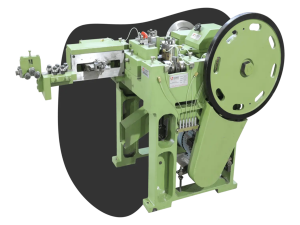

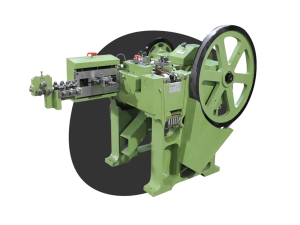

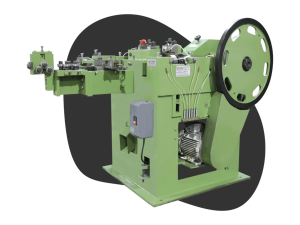

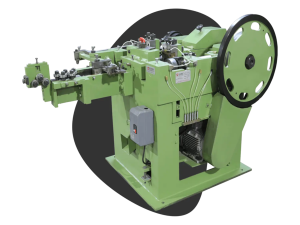

Wire Nail Making Machine

Versatility is the hallmark of our wire nail making machine. Suitable for producing a wide range of nail sizes, it’s perfect for manufacturers looking to diversify their product offerings. Its robust design ensures longevity and reliability, making it a wise investment for your manufacturing needs.

|  |  |

|  |

Key Features of Our Machines

Our concrete nail machines are engineered with precision and incorporate several features that set them apart:

- Durability: Constructed with high-quality materials, our machines are built to last and withstand the rigours of heavy use.

- User-Friendly Interface: Even with advanced functionalities, our machines are easy to operate, reducing the need for extensive training.

- Energy Efficiency: Designed to minimize energy consumption, our machines help reduce operational costs and are environmentally friendly.

Applications in Various Industries

The versatility of concrete nail machines makes them ideal for a wide range of applications. They are pivotal in industries such as:

- Building and Construction: For fast and reliable framing and roofing.

- Furniture Manufacturing: Essential for assembling robust furniture quickly.

- Packaging: For producing large quantities of pallets and crates.

Streamlining Your Production Process

Implementing our concrete nail machines in your production line means streamlined operations. You’ll reduce downtime, lower maintenance costs, and increase output, which translates to higher profitability and customer satisfaction.

Invest in Your Manufacturing Success Today

Choosing the right machinery is crucial for maintaining an edge in today’s market. With Gujarat Wire Products, you invest in reliability and innovation. Our concrete nail machines are not just tools; they are partners in your manufacturing journey.

Boost your production today with Gujarat Wire Products’ Concrete Nail Machines – where efficiency meets quality! By integrating one of our top-tier concrete nail machines into your operations, you set the stage for unmatched productivity and enduring success.

Contact information and how to order

To order concrete nail machines from Gujarat Wire Products, you can contact us through the following channels:

– Phone: +91-9824456375

– Email: info@gujaratwireproducts.com

– Website: www.gujaratwireproducts.com/contact-us

Read About: Wire Nail Making Machine

Please visit our official Facebook Page for updates from us.