Blog

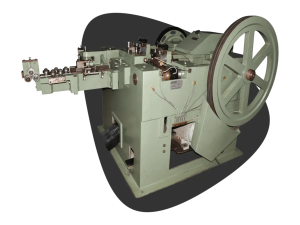

Roofing Nail Machine

Discover high-speed and versatile roofing nail machines at Gujarat Wire Products. Enhance your production efficiency and nail quality with our top-tier machines designed for precision and durability. Choose the best fit for your needs and take your manufacturing process to the next level.

Roofing Nail Machines: Precision and Efficiency for Your Needs

When it comes to roofing, the quality and type of nails used can make a significant difference. This is where specialized roofing nail machines come into play. Gujarat Wire Products, a leading manufacturer in this domain, offers top-tier roofing nail machines designed to meet the diverse needs of the construction industry.

Types of Roofing Nail Machines

Gujarat Wire Products provides two primary types of roofing nail machines: High-Speed Wire Nail Machines and Wire Nail Machines. Each type offers unique features and benefits, ensuring that you get the best fit for your specific requirements.

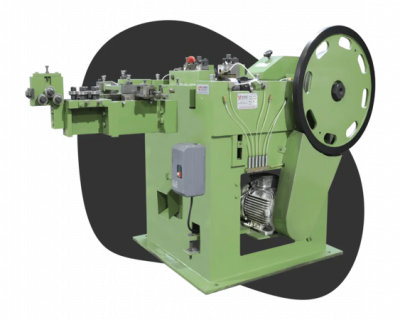

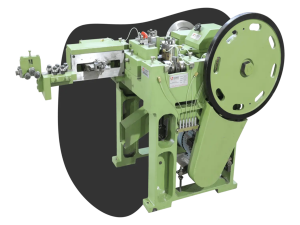

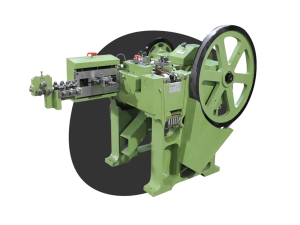

High-Speed Nail Making Machine

High-Speed Wire Nail Machines are designed for efficiency and speed. They are ideal for large-scale production where time and output are critical. These machines can produce a high volume of nails quickly without compromising on quality.

|  |  |

Key Features:

- High Output: Capable of producing thousands of nails per hour.

- Precision: Ensures each nail is crafted to exact specifications.

- Durability: Built with robust materials to withstand continuous operation.

- Efficiency: Minimizes waste and optimizes raw material usage.

These machines are perfect for industries that demand high-volume production with consistent quality. They significantly reduce production time and labour costs, making them a valuable investment for large-scale operations.

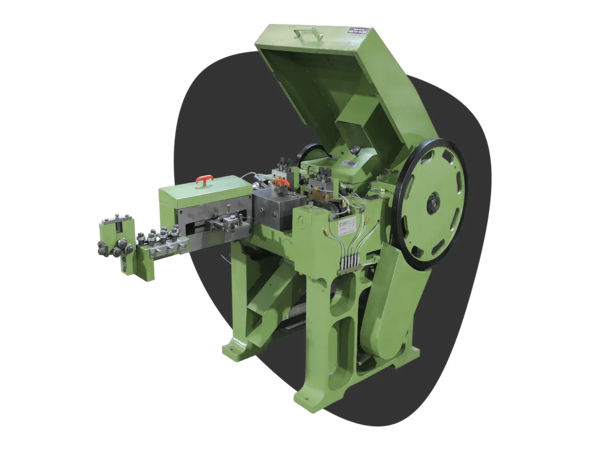

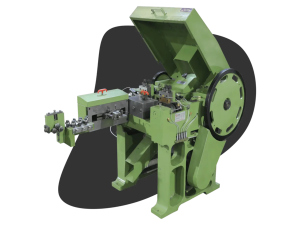

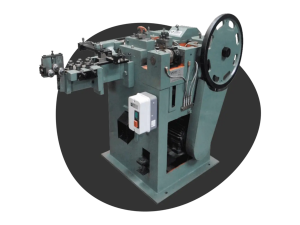

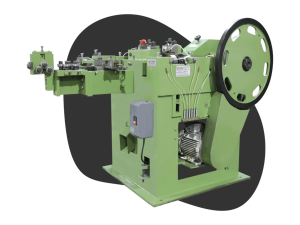

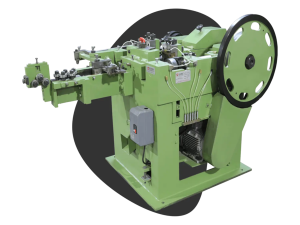

Wire Nail Making Machine

Wire Nail Machines, on the other hand, offer versatility and precision. They are suitable for both large and small-scale productions, providing flexibility and reliability.

|  |  |

|  |

Key Features:

- Versatility: Suitable for producing a variety of nail sizes and types.

- Reliability: Ensures consistent performance with minimal maintenance.

- Cost-Effective: Offers excellent value for money with high production efficiency.

- User-Friendly: Easy to operate and maintain, requiring minimal training.

These machines are ideal for businesses looking to produce high-quality nails without the need for extremely high-speed production. They strike a balance between efficiency and versatility, making them a popular choice for many manufacturers.

Benefits of Using Gujarat Wire Products’ Roofing Nail Machines

Choosing Gujarat Wire Products for your roofing nail machine needs comes with several benefits:

- Quality Assurance: All machines are manufactured to the highest standards, ensuring reliable and consistent performance.

- Advanced Technology: Incorporates the latest technology to enhance productivity and precision.

- Customer Support: Provides excellent after-sales support to ensure your machines run smoothly.

- Customization: Offers customized solutions to meet specific production requirements.

Why Invest in Roofing Nail Machines?

Investing in a high-quality roofing nail machine can significantly impact your production efficiency and product quality. Here are some reasons why you should consider investing in these machines:

- Increased Production Capacity: High-speed machines can drastically increase your production capacity, allowing you to meet large orders quickly.

- Enhanced Precision: Advanced machines ensure each nail is produced with precision, reducing the likelihood of defects.

- Cost Savings: Efficient machines reduce waste and lower production costs, improving your bottom line.

- Scalability: As your business grows, these machines can scale with your production needs, providing long-term value.

Conclusion

Roofing nail machines are an essential investment for businesses in the construction industry. Gujarat Wire Products offers high-speed and versatile wire nail machines designed to meet diverse production needs. By choosing the right machine, you can enhance your production efficiency, reduce costs, and ensure high-quality output.

Contact information and how to order

To order Roofing Nail Machines from Gujarat Wire Products, you can contact us through the following channels:

– Phone: +91-9824456375

– Email: info@gujaratwireproducts.com

– Website: www.gujaratwireproducts.com/contact-us

Read About: Wire Nail Machine Manufacturer

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.