Blog

Furniture Nail Machine

Discover top-quality Furniture Nail Machines at Gujarat Wire Products. Choose between high-speed wire nail machines for high-volume production and versatile wire nail machines for various nail types. Enhance your furniture manufacturing with precise, efficient, and durable nail machines. Contact us to boost your production process today!

Top Furniture Nail Machines

Furniture manufacturing requires precision, and quality nails are crucial. At Gujarat Wire Products, we understand this need. We offer a range of Furniture Nail Machines designed to meet your specific requirements. Our machines are reliable, efficient, and perfect for producing high-quality nails.

The Importance of Quality Nail Machines

Quality furniture requires high-quality nails. The right nail ensures durability and stability. Poor-quality nails can compromise the integrity of furniture. This chooses nail machines vital. Our Furniture Nail Machines provide the precision and quality needed for exceptional furniture manufacturing.

Types of Furniture Nail Machines

We offer two main types of Furniture Nail Machines: High-Speed Wire Nail Machines and Wire Nail Machines. Each type has unique features tailored to meet diverse manufacturing needs.

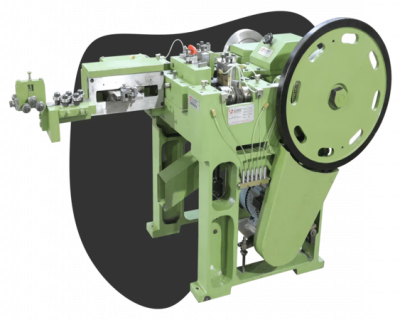

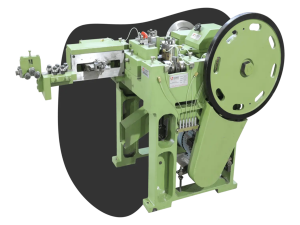

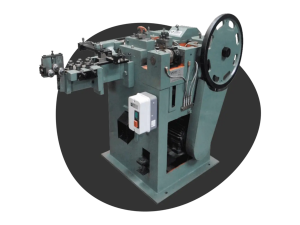

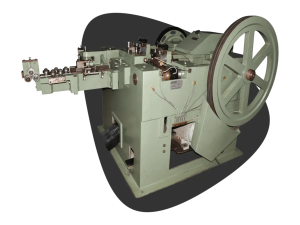

1. Enhanced Productivity with High Speed Wire Nail Making Machine:

Our High-Speed Wire Nail Machines are designed for efficiency. They produce a high volume of nails in a short time. This makes them ideal for large-scale furniture manufacturing. Key features include:

- High Production Rate: These machines can produce a large number of nails quickly. This helps in meeting high demand efficiently.

- Precision and Accuracy: The nails produced are precise and uniform. This ensures the nails fit perfectly in furniture, enhancing its durability.

- Durability: Built with robust materials, these machines are durable and long-lasting. They require minimal maintenance, reducing downtime.

- User-Friendly: Easy to operate, these machines come with user-friendly interfaces. This makes them suitable for both experienced operators and beginners.

|  |  |

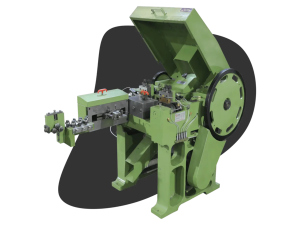

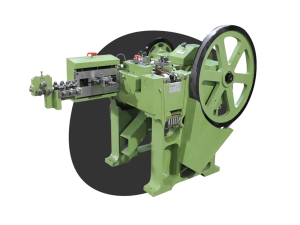

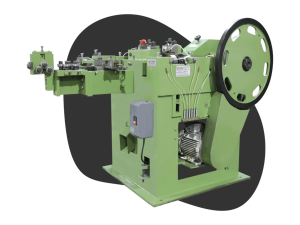

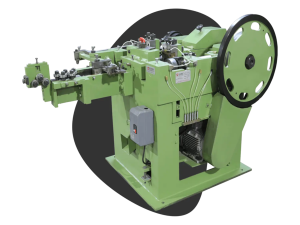

2. Versatility with Wire Nail Making Machine:

Wire Nail Machines are perfect for manufacturers looking for reliable and consistent performance. They are versatile and can produce various types of nails. Key features include:

- Versatility: These machines can produce different sizes and types of nails. This flexibility is beneficial for diverse furniture manufacturing needs.

- Consistency: The nails produced are consistent in size and quality. This ensures uniformity in furniture assembly, contributing to its strength and aesthetics.

- Energy-Efficient: Designed to consume less power, these machines are energy-efficient. This reduces operational costs and enhances sustainability.

- Cost-Effective: Wire Nail Machines offer great value for money. They are affordable and provide excellent return on investment.

|  |  |

|  |

Why Choose Gujarat Wire Products?

Choosing the right manufacturer for Furniture Nail Machines is crucial. Here’s why Gujarat Wire Products stands out:

- Expertise and Experience: We have years of experience in manufacturing high-quality nail machines. Our expertise ensures we deliver reliable and efficient machines.

- Customer Support: Our customer support team is always ready to assist. We provide comprehensive support to ensure our machines’ smooth operation and maintenance.

- Innovation: We continuously innovate to improve our machines. Our goal is to provide the latest technology to enhance your manufacturing process.

- Quality Assurance: All our machines undergo rigorous quality checks. We ensure that every machine meets the highest standards of quality and performance.

Applications of Furniture Nail Machines

Furniture Nail Machines are used in various applications in the furniture manufacturing industry. They are essential for producing nails for:

- Wooden Furniture: High-quality nails are crucial for assembling wooden furniture. Our machines ensure the nails are strong and durable.

- Upholstered Furniture: Upholstered furniture requires specialized nails. Our machines can produce nails that are perfect for this purpose.

- Outdoor Furniture: Nails used in outdoor furniture must withstand weather conditions. Our machines produce nails that are resistant to corrosion and wear.

Conclusion

Investing in high-quality Furniture Nail Machines is crucial for producing durable and reliable furniture. At Gujarat Wire Products, we offer the best machines designed to meet your specific needs. Whether you need high-speed production or versatile nail types, we have the perfect solution. Explore our range of Furniture Nail Machines and enhance your manufacturing process with precision and efficiency.

Contact information and how to order

To order Furniture Nail Machines from Gujarat Wire Products, you can contact us through the following channels:

– Phone: +91-9824456375

– Email: info@gujaratwireproducts.com

– Website: www.gujaratwireproducts.com/contact-us

Read About: Wire Nail Making Machine

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.