Blog

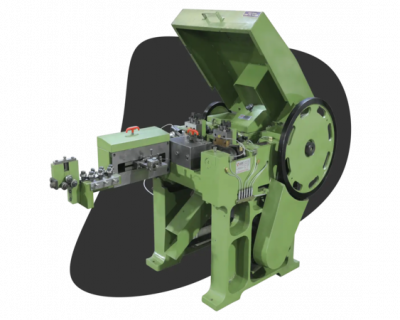

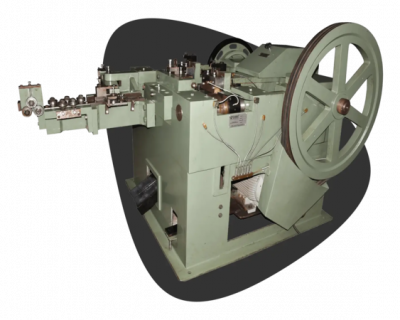

Wire Nail Machine

Maximize Productivity and Efficiency with a State-of-the-Art Wire Nail Machine

In today’s fast-paced and highly competitive manufacturing industry, maximizing productivity and efficiency is key to staying ahead of the game. One of the most crucial factors in achieving this is having the right tools and equipment in place to streamline production processes and minimize downtime. This is where a state-of-the-art wire nail machine comes in. With advanced technology and precision engineering, these machines are designed to produce high-quality wire nails at a rapid pace, with minimal operator intervention.

Whether you’re running a small workshop or a large-scale production facility, a wire nail machine can help you boost your output and reduce your operating costs, while maintaining strict quality control standards. In this article, we’ll explore the benefits of using a wire nail machine and what you need to consider when choosing the right one for your business. So, let’s get started and discover how you can take your manufacturing operations to the next level.

Benefits of Using a Wire Nail Machine

One of the main benefits of using a wire nail machine is that it offers significant improvements in productivity and efficiency. With a wire nail machine, you can produce many nails in a short amount of time, without the need for manual labour. This means you can increase your output while reducing your operating costs. Moreover, advanced features like automatic feeding and cutting enhance wire nail machines, minimizing operator intervention and boosting production speed.

Another benefit of using a wire nail machine is that it allows for consistent quality control. Designed to produce nails to exact specifications, wire nail machines ensure that each nail meets high-quality standards. You can be confident that your nails will be uniform and consistent, essential for proper fit and function in the end product.

Lastly, using a wire nail machine can help you reduce waste and minimize the environmental impact of your manufacturing operations. With precise cutting and feeding mechanisms, wire nail machines produce nails with minimal scrap material. This means that you can reduce the amount of raw materials you need to purchase and minimize the amount of waste you generate. Additionally, many wire nail machines are designed with energy-efficient features that can help you reduce your energy consumption and lower your carbon footprint.

Different Types

There are several different types of wire nail machines available on the market, each with its own unique features and capabilities. The most common types of wire nail machines include:

Factors to Consider Before Purchasing a Wire Nail Machine

When choosing a wire nail machine, there are several important factors to consider. These include:

- Production Capacity: The production capacity of the machine is one of the most important factors to consider. You’ll need to determine how many nails you need to produce per day and choose a machine that can meet your production needs.

- Nail Size and Shape: Different machines are designed to produce nails in different sizes and shapes. You’ll need to choose a machine that can produce the specific type of nail you need for your manufacturing operations.

- Quality Control: Quality control is essential for ensuring that your nails meet the required standards. You’ll need to choose a machine that is designed to produce nails to exact specifications and has features that allow you to monitor and control the quality of the nails.

- Maintenance and Support: Like any piece of equipment, wire nail machines require regular maintenance and upkeep. You’ll need to choose a machine that is easy to maintain and comes with reliable technical support.

By taking these factors into consideration, you can choose a wire nail machine that meets your specific needs and requirements.

Features

State-of-the-art wire nail machines are equipped with advanced features and capabilities that allow for maximum productivity and efficiency. Some of the key features of a state-of-the-art wire nail machine include:

- Automatic feeding and cutting mechanisms that minimize operator intervention and improve production speed.

- Advanced control systems that allow you to monitor and control the quality of the nails.

- Energy-efficient features that help you reduce your energy consumption and lower your carbon footprint.

- Easy-to-use interfaces that make it simple for operators to set up and operate the machine.

- High-speed motors and cutting blades that allow for rapid production of nails.

By choosing a state-of-the-art wire nail machine with these advanced features, you can take your manufacturing operations to the next level and achieve maximum productivity and efficiency.

How to Maximize Productivity and Efficiency with a Wire Nail Machine

To maximize the productivity and efficiency of your wire nail machine, there are several best practices you should follow:

- Ensure that the machine is properly maintained and serviced on a regular basis to prevent breakdowns and minimize downtime.

- Train operators on the proper use of the machine to ensure that it is being used to its full potential.

- Monitor production metrics such as output, quality, and downtime to identify areas for improvement.

- Use automation and technology to streamline production processes and minimize operator intervention.

By following these best practices, you can ensure that your wire nail machine is operating at maximum efficiency and productivity, allowing you to meet your production goals and stay ahead of the competition.

Maintenance and Care Tips for Your Wire Nail Machine

Proper maintenance and care are essential for ensuring that your nail machine operates at peak performance and has a long lifespan. Some maintenance and care tips to keep in mind include:

- Regularly inspect the machine for signs of wear and tear or damage.

- Clean the machine on a regular basis to prevent the build-up of dirt and debris.

- Lubricate the machine’s moving parts to prevent friction and wear.

- Replace worn or damaged parts as needed to prevent further damage to the machine.

By following these maintenance and care tips, you can ensure that your nail machine operates smoothly and reliably for many years to come.

Cost-Benefit Analysis of Investing in a Wire Nail Machine

Investing in a nail machine can be a significant expense for many manufacturing operations, so it’s important to conduct a cost-benefit analysis before making a purchase. Some factors to consider in a cost-benefit analysis include:

- The potential savings in labour costs and increased productivity.

- The potential for increased revenue due to higher output and improved quality control.

- The cost of the machine itself, including installation and setup.

- The potential for reduced waste and lower environmental impact.

By conducting a thorough cost-benefit analysis, you can determine whether investing in a wire nail machine is a sound financial decision for your manufacturing operation.

Conclusion

In today’s fast-paced and highly competitive manufacturing industry, maximizing productivity and efficiency is essential for staying ahead of the competition. A state-of-the-art nail machine can help you achieve these goals by streamlining production processes, reducing labour costs, and improving quality control. By understanding the different types of wire nail machines, considering the important factors before purchasing, and following best practices for maximizing productivity and efficiency, you can take your manufacturing operations to the next level. With proper maintenance and care, your wire nail machine can provide reliable and efficient production for many years to come.

Contact information and how to order

To order Concrete Nail Machines from Gujarat Wire Products, you can contact us through the following channels:

– Phone: +91-9824456375

– Email: info@gujaratwireproducts.com

– Website: www.gujaratwireproducts.com/contact-us

Read About: Panel Pin Making Machine Manufacturer

Please visit our official Facebook Page for updates from us.