Blog

Automatic Wire Nail Making Machine

Discover the best Automatic Wire Nail Making Machines from Gujarat Wire Products. Our machines boost efficiency, ensure consistent quality, and reduce operational costs. Choose from High-Speed Wire Nail Making Machines for rapid production or versatile Wire Nail Making Machines for varied production needs. Enhance your manufacturing today!

Top Automatic Wire Nail Making Machines for Efficient Production

Gujarat Wire Products excels in manufacturing Automatic Wire Nail Making Machines. These machines are designed for efficient and reliable nail production. Explore the types of machines we offer and their benefits.

Why Choose Automatic Wire Nail Making Machines?

Automatic Wire Nail Making Machines boost production efficiency. They reduce manual labour and ensure consistency in nail quality. Their automation enhances productivity and lowers operational costs. These machines cater to various production needs, making them ideal for manufacturers.

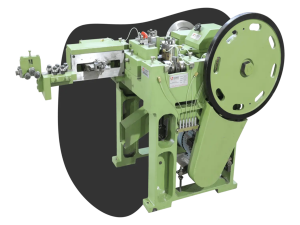

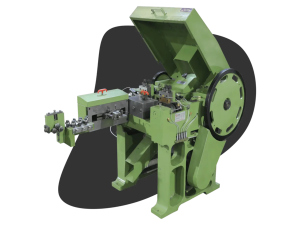

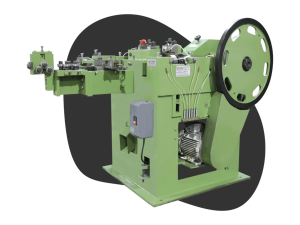

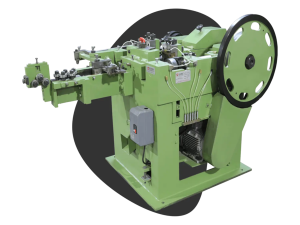

High Speed Wire Nail Making Machine

|  |  |

High-Speed Wire Nail Making Machines are designed for rapid production. They ensure high efficiency and consistent quality. These machines are perfect for large-scale manufacturing. Let’s delve into their features:

Key Features of High-Speed Wire Nail Making Machines

- High Production Speed: These machines can produce a large number of nails per minute.

- Consistency: They ensure uniform size and quality of nails.

- Durability: Built with robust materials, they promise long-lasting performance.

- User-Friendly: Easy to operate, reducing the need for skilled labor.

- Low Maintenance: Designed for minimal maintenance, ensuring continuous production.

Benefits of High-Speed Wire Nail Making Machines

- Increased Productivity: High-speed production means more nails in less time.

- Cost Efficiency: Reduced labor costs and high output lower the cost per nail.

- Quality Assurance: Consistent production quality meets industry standards.

- Versatility: Suitable for various nail sizes and types.

- Reliability: Robust design ensures uninterrupted operation.

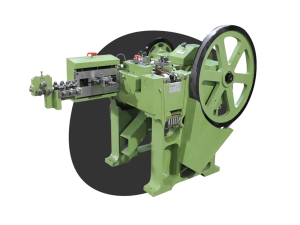

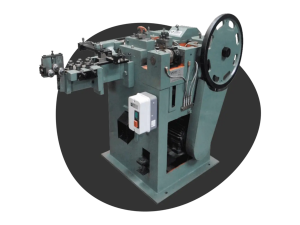

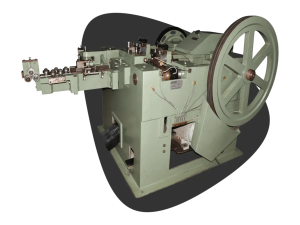

Wire Nail Making Machine

|  |  |

|  |

Wire Nail Making Machines are versatile and efficient. They cater to different production scales and nail types. Let’s explore their features and benefits:

Key Features of Wire Nail Making Machines

- Versatile Production: Capable of producing different types of nails.

- Efficiency: Designed for optimal energy use and productivity.

- Ease of Use: Simple operation and minimal training required.

- Durability: High-quality construction for long-term use.

- Flexibility: Adjustable settings for various nail sizes.

Benefits of Wire Nail Making Machines

- Cost-Effective: Economical operation and low energy consumption.

- Adaptability: Suitable for small to medium-scale production.

- Quality Production: Ensures nails meet precise specifications.

- User Convenience: Easy to operate with minimal maintenance.

- Sustainability: Energy-efficient design reduces environmental impact.

Why Gujarat Wire Products?

Gujarat Wire Products stands out in the nail-making industry. Our machines are designed with cutting-edge technology. We prioritize quality and efficiency in all our products. Here’s why you should choose us:

- Expertise: Years of experience in manufacturing nail-making machines.

- Innovation: Continual improvement and adoption of advanced technology.

- Customer Support: Dedicated service and support for our customers.

- Quality Assurance: Strict quality control measures ensure top-notch products.

- Customization: Machines tailored to meet specific production needs.

Conclusion

Automatic Wire Nail Making Machines from Gujarat Wire Products are the key to efficient and high-quality nail production. Whether you need high-speed machines for large-scale manufacturing or versatile machines for varied production, we have the right solution for you. Our machines are designed for durability, efficiency, and ease of use, making them a valuable addition to any manufacturing setup. Choose Gujarat Wire Products for your nail-making needs and experience the benefits of advanced technology and exceptional customer support.

Contact information and how to order

To order Concrete Nail Machines from Gujarat Wire Products, you can contact us through the following channels:

– Phone: +91-9824456375

– Email: info@gujaratwireproducts.com

– Website: www.gujaratwireproducts.com/contact-us

Read About: Wire Nail Machine

Please visit our official Facebook Page for updates from us.