Blog

What Is A Nails Manufacturing Process?

Nails Manufacturing Process

Your knowledge of nails stops at the nuts and bolts; a metal rod that is pointing at one side. Utilizing it against a hammer might not spark your curiosity about the production of nails. Moreover, one might not know the nail parts and be further stunned to know there are various kinds of nails.

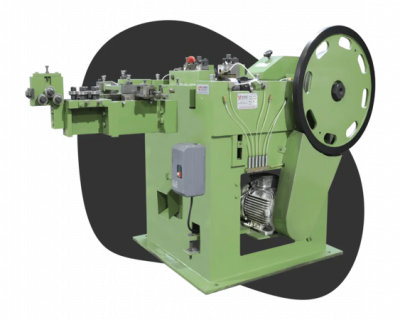

That aside, the nail pinnacle is one that you need to get related to. The breakdown of the nail creation line incorporates the Nails Manufacturing machine equipment, wire drawing machine, and nail garments washer among a variety of gear for nail-making the machine. Explore our High-speed wire nail making machine

Process

The Nails Manufacturing process includes wire drawing, molding, and cleaning. To create the curl, we need a unique round steel shape. Once you shape and secure the bottom and head, the nail will be complete. After polishing the coil, you will have a finished nail.

The operation in the nail manufacturing process as such:

Wire Drawing:

The primary stage and its offset include shell stripping followed by descaling the wire. You can draw the coil to the diameter you want.

This metalworking process diminishes the cross-section of a wire. Wire drawing has numerous applications and isn’t entitled to nail making alone. By being able to minimize wire cross-section by passing the wire through either a series of dies, this manufacturing procedure is an acquired concept.

Nail Making:

The Nails Manufacturing machine and its auxiliary parts then make the necessary nail.

Nail Polishing:

The nail-making machine punches the head to form a cap, your nail will require cleaning. It is a task destined for the nail cleaning machine. It blends nails in with sawdust simultaneously to help accomplish the necessary brightness. And the last measuring & packing.

Read More: WHAT IS A COIL NAIL MAKING MACHINE? & IT’S PROCESS

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.