Blog

What Is A Coil Nail Making Machine? & It’s Process

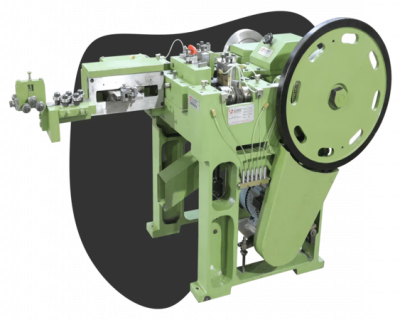

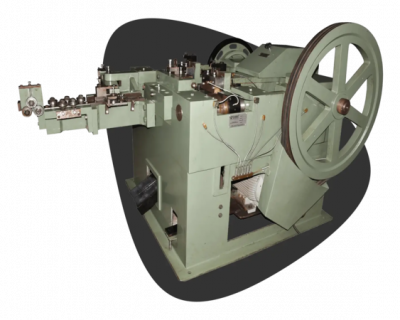

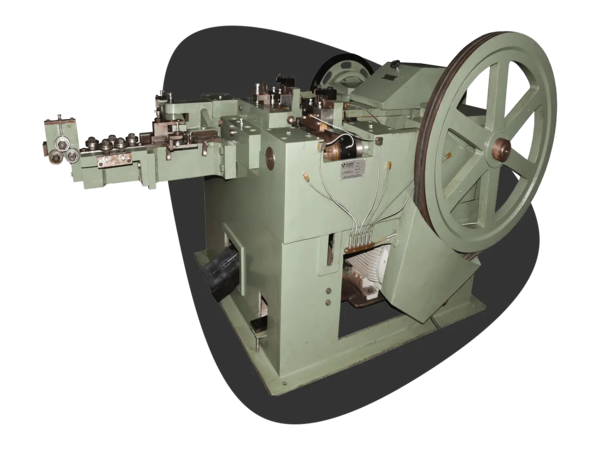

Coil Nail Making Machine

A Coil Nail Making Machine, also referred to as a coil nail collator, is a nail-making equipment used to produce coil nails. Nail guns commonly use these nails.

The loop nail consists of a specific number of nails of the same shape and distance. Copper-plated steel wire connects these nails. The wire connects the nails at an angle of β in relation to the middle line of each nail. Subsequently, it is coiled or bundled together. Coil nails can save effort and raise productivity greatly. Explore our Wire Nail Machine

Coil Nails are utilized in Nailers. One worker with a pneumatic hammer and a set of rack nails can replace a few groups that utilize conventional hammers and ordinary nails. The specialist finds this method to be the safest since it automates everything, reducing the risk of damage or injury to a minimum.

In construction, wooden house-building, wooden box packaging production, attaching wooden beds, euro beds and holders, and wooden structures requiring strong bonding, coil nails serve as a widely utilized option. There are three categories of coil nails: screw shank coil nails, ring coil nails, and smooth shank coil nails.

Coils Nail Manufacturing

The production of Paper Strip Nails for rack-type pneumatic nailing hammers involves using a specialized collator machine. Coil Nail Making Machine collects nails onto paper cuts. The collator machine utilizes ring knife nails, screw knife nails, or smooth knife nails as spacers. The collator machine has a built-in staining and painting system.

Process of Making Coil Nails

First, make wire nails. Then, use the thread rolling machine to create different types of threaded nails, such as ring-shaped or screw-shaped nails. Afterwards, place these nails onto the vibration plate, which will feed them into the Coil Nail Making Machine for welding them into coils.

Read More: What is a Concrete Nail?

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.