Blog

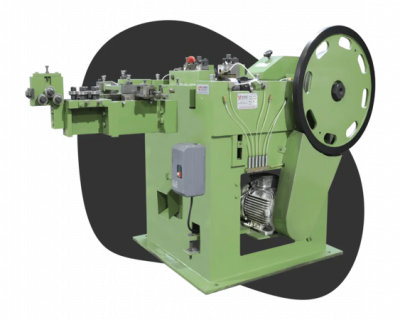

Nails Manufacturing Machine

Are you looking to take your nail production to the next level? Look no further! In this fast-paced world, staying ahead of the competition is crucial. That’s why it’s essential to stay updated with the latest innovations in nails manufacturing machines. With these cutting-edge technologies, you can significantly boost your nail production, increase efficiency, and improve the overall quality of your products. From automated machines that streamline the entire manufacturing process to advanced systems that ensure precision and consistency, the possibilities are endless.

Benefits of Using the Latest Nails Manufacturing Machines

Investing in the latest nails manufacturing machines can bring a plethora of benefits to your business. Let’s explore some of the advantages you can expect when leveraging these cutting-edge technologies.

Increased Productivity

One of the primary benefits of using the latest nails manufacturing machines is increased productivity. These machines are designed to optimize production processes, allowing you to produce more nails in less time. With higher production volumes, you can fulfil larger orders, expand your customer base, and ultimately, grow your business.

Automation plays a crucial role in enhancing productivity. By automating repetitive tasks, you can free up your workforce to focus on more complex and value-added activities. This not only increases output but also improves employee morale and job satisfaction.

Improved Quality Control

Quality control is a top priority in the nail industry, and the latest nails manufacturing machines can help you achieve consistently high-quality products. These machines are equipped with advanced sensors and monitoring systems that detect defects and inconsistencies in real-time. By identifying and rectifying issues early in the production process, you can ensure that only flawless nails reach your customers.

Precision is another aspect that contributes to improved quality control. Laser-guided machines, for example, enable you to produce nails with exceptional accuracy and consistency. This level of precision eliminates human error and ensures that every nail meets the exact specifications.

Cost Savings

While investing in the latest nails manufacturing machines may seem like a significant upfront cost, it can lead to substantial long-term savings. By automating processes and optimizing production, these machines help reduce labour costs and minimize material waste. Additionally, increased productivity means you can produce more nails with the same resources, further maximizing your return on investment.

Efficiency in nail production also translates to energy savings. Many of the latest machines are designed to be energy-efficient, consuming less power while delivering higher output. This not only reduces your carbon footprint but also lowers your utility bills.

Factors to Consider When Choosing a Nails Manufacturing Machine

Choosing the right nails manufacturing machine for your business is a critical decision that can impact your production efficiency and overall success. Here are some factors to consider when evaluating your options:

Production Capacity

The production capacity of a machine refers to the number of nails it can produce within a specific timeframe. It is essential to assess your current and projected production volumes to ensure that the machine you choose can meet your requirements. Consider factors such as market demand, growth projections, and seasonal fluctuations when determining the appropriate capacity.

Machine Flexibility

Flexibility is crucial in a rapidly evolving industry like nails manufacturing. Look for machines that offer versatility and can handle a wide range of nail types, shapes, and sizes. This flexibility allows you to cater to diverse customer preferences and adapt to changing market trends.

Maintenance and Support

Regular maintenance is vital to keep your nails manufacturing machine in optimal condition. Consider the maintenance requirements of different machines and ensure that you have the necessary resources and expertise to perform routine upkeep. Additionally, check the availability of technical support and spare parts to ensure minimal downtime in case of any issues.

Tips for Optimizing Nail Production with the Latest Machines

Investing in the latest nails manufacturing machines is just the first step towards maximizing your production efficiency. To reap the full benefits of these technologies, consider implementing the following tips:

Employee Training and Engagement

Proper training is crucial to ensure that your employees can effectively operate and maintain the new machines. Provide comprehensive training programs that cover machine operation, safety procedures, and troubleshooting techniques. Engage your employees by seeking their input and feedback, as they are the ones working closely with the machines on a day-to-day basis.

Streamline Production Processes

Take the opportunity to streamline your production processes when implementing new machines. Identify areas of inefficiency and eliminate unnecessary steps or bottlenecks. Consider reorganizing your production floor layout to optimize workflow and minimize the time spent on non-value-added activities.

Regular Maintenance and Calibration

To keep your machines running smoothly and prevent unexpected downtime, establish a regular maintenance schedule. Perform routine checks, cleaning, and calibration to ensure optimal performance. Regularly inspect and replace worn-out parts to avoid any disruptions in production.

Maintenance and Troubleshooting Tips for Nails Manufacturing Machines

To ensure the longevity and optimal performance of your nails manufacturing machines, follow these maintenance and troubleshooting tips:

Regular Cleaning

Regularly clean your machines to remove dust, debris, and residue that can accumulate over time. Use appropriate cleaning agents and follow the manufacturer’s guidelines to avoid damaging sensitive components.

Lubrication

Proper lubrication is essential to keep the moving parts of your machines functioning smoothly. Follow the recommended lubrication schedule and use the specified lubricants to prevent friction and wear.

Monitoring and Calibration

Monitor your machines regularly to detect any signs of malfunction or performance issues. Calibrate the machines as per the manufacturer’s instructions to maintain accuracy and consistency.

Prompt Repairs

Address any machine issues promptly to prevent further damage and minimize downtime. If you encounter any problems beyond your expertise, contact the manufacturer or a qualified technician for assistance.

Conclusion and Future Trends in Nails Manufacturing Machine Innovations

In conclusion, the latest nails manufacturing machines offer incredible opportunities for boosting nail production, improving quality, and increasing efficiency. With automation, 3D printing, and laser-guided precision, you can revolutionize your production line and elevate your business to new heights. By carefully considering factors such as production capacity, machine flexibility, and maintenance requirements, you can choose the right machine for your business.

Remember to optimize your nail production by investing in employee training, streamlining processes, and prioritizing regular maintenance. Real-life case studies demonstrate how businesses have successfully leveraged innovative machines to scale their operations, improve quality control, and reduce costs.

To find the latest nails manufacturing machines, explore industry trade shows, online marketplaces, and manufacturer websites. Follow proper maintenance practices, such as regular cleaning, lubrication, monitoring, and prompt repairs, to ensure the longevity and optimal performance of your machines.

Looking ahead, the future of nails manufacturing machine innovations holds even more exciting possibilities. Advancements in artificial intelligence, robotics, and smart technologies are expected to further enhance production efficiency and quality control. Stay informed and embrace these future trends to stay ahead of the competition and continue growing your nail business.

Read About: Katedar Wire ki Machine

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.