Blog

Katedar Wire ki Machine

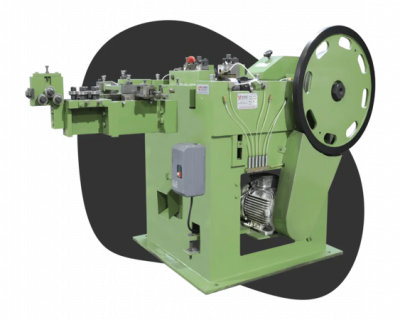

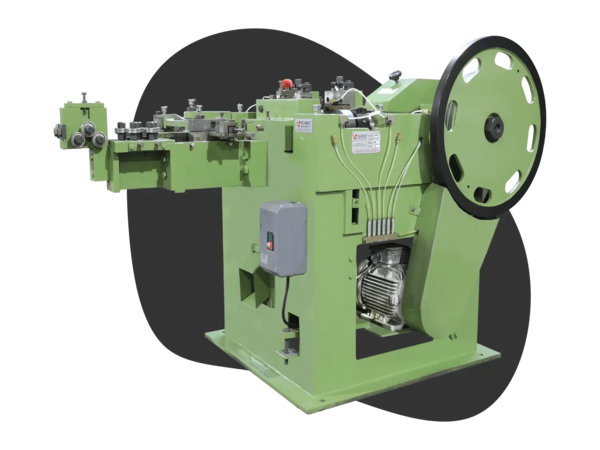

Revolutionize Your Fencing with Our Cutting-Edge Katedar Wire ki Machine

In the realm of wire manufacturing, precision and efficiency are paramount, and Gujarat Wire Products stands as a stalwart in delivering just that. As a leading manufacturer, we specialize in Katedar Wire ki Machines, setting new benchmarks in the industry.

Unveiling Excellence in Machinery

At Gujarat Wire Products, our commitment to excellence is evident in every Katedar Wire ki Machine we produce. We design our state-of-the-art machinery with precision engineering for optimal performance and longevity. Whether you’re a small-scale enterprise or a large manufacturing unit, our machines cater to varied production needs with efficiency and reliability.

Key Features

- Precision Engineering: Our machines are crafted with meticulous attention to detail, ensuring precision in every wire produced.

- Versatility: Adaptability is crucial in the manufacturing industry. Our machines are designed to produce a variety of barbed wire types, meeting diverse market demands.

- Efficiency: Time is money, and our machines are built to optimize production cycles, maximizing output without compromising on quality.

- Durability: We understand the importance of robust machinery in a manufacturing setup. Katedar Wire ki Machines withstand continuous production rigours.

Why Choose Gujarat Wire Products?

- Industry Expertise: With decades of experience, Gujarat Wire Products has garnered a reputation for being a reliable and innovative force in wire manufacturing.

- Customization: Recognizing that each client’s needs are unique, we offer customization options, ensuring our Katedar Wire ki Machines align perfectly with specific requirements.

- Quality Assurance: Quality is non-negotiable for us. Each machine undergoes rigorous testing to meet international quality standards, guaranteeing durability and performance.

- Technical Support: Our commitment extends beyond the sale. We provide comprehensive technical support, ensuring seamless integration of our machines into your production line.

Elevate Your Wire Production

Gujarat Wire Products takes pride in contributing to the success of businesses through our cutting-edge Katedar Wire ki Machines. Elevate your wire production capabilities, streamline processes, and enhance the quality of your output with our machinery.

Conclusion

In the competitive landscape of wire manufacturing, choosing the right machinery is pivotal. Gujarat Wire Products not only manufactures Katedar Wire ki Machines but empowers businesses to thrive through innovation and reliability. Explore the possibilities with us, and witness the transformation of your production capabilities.

Are you ready to revolutionize your wire manufacturing process? Explore our Katedar Wire ki Machines today at Gujarat Wire Products. Your journey to precision and efficiency starts here!

Contact information and how to order

To order Katedar Wire ki Machines from Gujarat Wire Products, you can contact us through the following channels:

– Phone: +91-9824456375

– Email: info@gujaratwireproducts.com

– Website: www.gujaratwireproducts.com/contact-us

Read About: Chain Link Machine

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.