Blog

Galvanized Nail

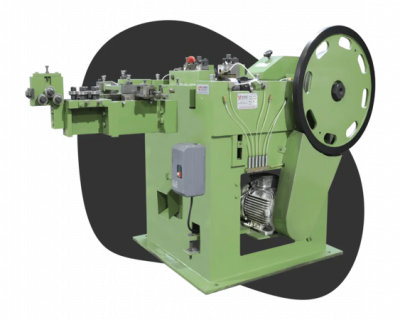

As nails made of iron or steel resist erosion, there was a requirement for some kind of covering to forestall rust. Normal components can consume various grades of steel. This coating technique includes covering the outer layer of iron or steel with zinc. Previously, people used to plunge the nails into liquid zinc or cover them with galvanic paint. Explore our high speed wire nail making machine

Three Kinds of Galvanization

There are three kinds of galvanization: electro-galvanization, mechanical galvanizing, and hot-dip galvanization. Nowadays, people commonly use hot-dip galvanization to protect iron and steel surfaces from corrosion. In simple terms, galvanized nails are nothing more than steel or iron nails coated with zinc to prevent corrosion. In the hot-dip galvanization process, the steel immerses in liquid zinc at a temperature of 860 °F. This covering, when uncovered, structures a layer of zinc oxide and zinc carbonate. This protects the internal steel or iron from exposure to climatic elements that lead to corrosion.

Nails can likewise galvanize through electroplating. The nail with electroplating is not considered efficient in combating corrosion. Comparatively, individuals exposed to hot-dip galvanization provide a better comparison.

When we use electroplating for galvanization, it applies only a thin layer of zinc to the nail. This layer may break when continuously exposed to corrosive elements. On the other hand, people always prefer hot-dip galvanization because it creates a thicker layer of zinc that effectively prevents corrosion for a longer period.

While the electroplated galvanized nail is regularly sometimes to be smooth and sparkly, hot-dipped ones are harsh in looks.

Usually, people choose electroplated nails for indoor applications, while they prefer hot-dipped nails for outdoor use. However, electroplated galvanized nails are not suitable for redwood or treated timber because the chemicals in the wood can cause the nails to erode. Galvanized nails come in various sizes, which are measured in millimetres. However, in the U.S., people often use the term ‘pennies’ to refer to these sizes.

Therefore, people prefer galvanized nails over other types due to their durability, thanks to the zinc coating that helps resist corrosion.

Read more: WIRE DRAWING MACHINE PROCESS

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.