Nail Making

Machine

Wire

Products

Welcome To

Gujarat Wire Products

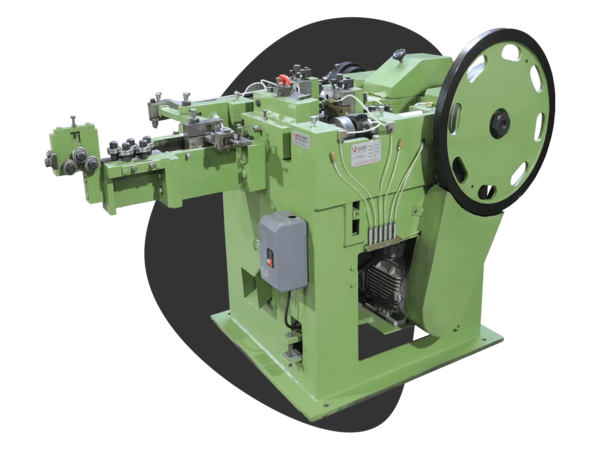

Gujarat Wire Products is an ISO 9001:2008 company providing high-quality Wire Nail Making Machine in India and worldwide.

We Gujarat Wire Products as a global leader in Wire Nail Making Machine and Wire Drawing Machine since 1975, Not only in the Domestic market but also have a strong presence in the overseas market viz. Africa, the UK, Europe, Asia…. Etc.

We mainly deal in Roofing nail machines, Concrete nail machines, Umbrella type nail machines, Panel pin making machines, Shoe tacks nail machines, Wire Nail header machines, Kati machines, Kil machines, Khilli machines, Katatar machines, Barbed wire making machines, Katedar wire ki machine, Chainlink machine, Jali ki machine, Wire Nail press machine, grinder machine Spiral nail making machine, Wire Nail Making Machine, Ancillary Machine (WNP), Tools for Wire Nail Plant, Wire Drawing Machine & Ancillary Machine (WDP) as well as Special Purpose Machinery.

Wire Nail

Making

Machine

Making

Machine

Barrel

Drum

What Makes Us Unique?

Wire Nail Making Machine FAQs

How Technology is Changing Nail Making Machines?

In recent years, manufacturers have significantly shifted the design and manufacturing process of nail-making machines in the nail industry. With the help of technology, Wire Nail Making Machines are becoming more advanced, efficient, and eco-friendly. These machines are revolutionizing the nail industry, making producing high-quality nails easier, faster, and more cost-effective. From small-scale manufacturers to large-scale production facilities, these machines are changing the game for businesses of all sizes.

What is the Traditional Nail Making Process?

For centuries, nails have been made using a traditional process that involves heating and shaping a metal wire into the desired shape. This process was time-consuming, and labour-intensive, and often resulted in nails that were not uniform or shaped. Small-scale manufacturers used hammers and anvils to create nails, while large-scale production facilities utilized steam or hydraulic machines.

The traditional nail-making process had several drawbacks. It required a significant amount of manual labour, which made it expensive and time-consuming. It also resulted in nails that were not uniform or shaped, which made them difficult to use in construction projects. The traditional nail-making process utilized inefficient machines, resulting in significant waste and elevated production costs.

What are Problems With Traditional Nail Making Machines?

Traditional wire nail making machines had limited capabilities. They were often slow, inefficient, and required a lot of manual labour to operate. This made them expensive to use and difficult to maintain. Traditional nail-making machines were typically bulky and unwieldy, posing challenges when it came to mobility and repositioning.

Another problem with traditional Wire Nail Making Machines was their lack of precision. They were often unable to create nails that were uniform, in shape, or length. This made it difficult to use them in construction projects, where nails needed to be consistent in order to ensure structural stability.

What are Advancements in Nail Making Technology?

The advent of new technologies has completely changed the nail-making industry. Today, Wire Nail Making Machines are more advanced, efficient, and eco-friendly than ever before. They are capable of producing high-quality nails at a fraction of the cost and time required by traditional machines.

One of the biggest advancements in nail-making technology has been the development of automated machines. These machines are capable of producing nails at a high rate of speed, with little or no manual labour required. They are also capable of producing nails that are uniform in size, shape, and length, which makes them ideal for use in construction projects.

Additionally, advancements in computer technology have led to the development of Wire Nail Making Machines that are highly precise. These machines are capable of creating nails with a level of accuracy that was previously impossible. This has led to a significant reduction in waste and increased production efficiency.

How Technology is Revolutionizing the Nail Industry?

Technology is transforming the nail industry in a number of ways. For one, it is making Wire Nail Making Machines more efficient and cost-effective. Automated machines are capable of producing nails at a high rate of speed, with little or no manual labour required. This has led to a significant reduction in production costs and increased profitability for manufacturers.

Additionally, technology is making Wire Nail Making Machines more eco-friendly. Automated machines produce less waste than traditional machines, which reduces the environmental impact of the nail making process. This has become increasingly important as consumers become more environmentally conscious and demand products that are eco-friendly.

Furthermore, technology is making Wire Nail Making Machines more precise. This has led to a reduction in waste and an increase in production efficiency. Precise Wire Nail Making Machines are capable of creating nails that are uniform in size, shape, and length, which makes them ideal for use in construction projects. This has led to an increase in demand for nails produced using these machines.

What are the Benefits of Using Technology in Nail Making Machines?

There are a number of benefits to using technology in Wire Nail Making Machines. For one, it makes the nail making process more efficient and cost-effective. Automated machines are capable of producing nails at a high rate of speed, with little or no manual labor required. This has led to a significant reduction in production costs and increased profitability for manufacturers.

Additionally, technology makes Wire Nail Making Machines more eco-friendly. Automated machines produce less waste than traditional machines, which reduces the environmental impact of the nail making process. This has become increasingly important as consumers become more environmentally conscious and demand products that are eco-friendly.

Furthermore, technology makes Wire Nail Making Machines more precise. This has led to a reduction in waste and an increase in production efficiency. Precise Wire Nail Making Machines are capable of creating nails that are uniform in size, shape, and length, which makes them ideal for use in construction projects. This has led to an increase in demand for nails produced using these machines.

How many types of Nail Making Machines Available?

There are a number of different types of nail making machines available on the market today. The most common types include:

- Wire Nail Making Machine

- Coil Nail Making Machine

- Plastic Strip Nail Making Machine

- Paper Strip Nail Making Machine

- Roofing Nail Making Machine

Each type of nail making machine has its own unique features and benefits. Wire nail making machines produce small nails best, while coil nail making machines are ideal for producing large nails. Nails used in the construction of wooden pallets are best produced using plastic strip nail making machines, while the furniture industry benefits from nails produced using paper strip nail making machines. For roofing applications, Roofing Wire Nail Making Machines are the most suitable for producing nails.

What are Features to Consider When Choosing a Nail Making Machine?

When choosing a nail making machine, there are several features that you should consider. These include:

- Production Capacity: How many nails can the machine produce per hour?

- Nail Size: What size of nails can the machine produce?

- Nail Type: What type of nails can the machine produce?

- Power Source: What type of power source does the machine require?

- Automation: Does the machine operate fully automatically or does it require manual labor to operate?

- Quality: What is the quality of the nails produced by the machine?

- Cost: How much does the machine cost to purchase and operate?

You can choose a Wire Nail Making Machine that best suits your needs and budget by considering these factors.

What is Future of Nail Making Machines?

The future of nail making machines is bright. As technology continues to advance, we can expect to see even more efficient, cost-effective, and eco-friendly machines on the market. Additionally, we anticipate the development of highly precise machines that can manufacture nails with consistent size, shape, and length.

Furthermore, we can expect to see a greater emphasis on sustainability in the Wire Nail Making Machine industry. As consumers become more environmentally conscious, manufacturers will be under increasing pressure to produce nails that are eco-friendly. This will lead to the development of new technologies and processes that reduce the environmental impact of the nail making process.