Blog

Designing of Nails

When manufacturers develop nail, they create framing dies and establish production cycles to deliver the nail in large quantities. Currently, the United States produces a majority of the 300 different types of nails available.

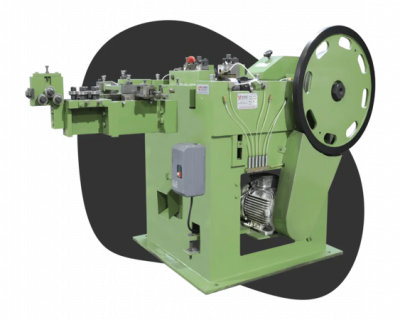

Most nails have an expansive round head. Completing nails have a tough head which permits them to be subset below the outer layer of the material and covered over to create a smooth completion. Upholstery nails have decorative tops. We use twofold-headed nail to secure wooden structures during concrete pouring. We drive the nail up to the first head, which leaves the second head sticking out. The protruding head makes it easy to remove the nails and quickly dismantle the structures once the concrete has hardened. Explore our wire nail making machine

Typically, we design the sharp edge to be round and smooth for ease of use. When you need a strong and long-lasting grip, we utilize sharp edges with serrations, annular depressions, twisting woodwinds, or helical strings. To improve durability, we can also apply thermoplastic coatings to the shaft. These coatings heat up due to friction when you drive the nail, and then they cool and set to securely hold the nail in place. We determine the size of the blade based on the type of nail you’re using. Most nail, called normal nail, have a generally huge width. Box nails, initially used to make slenderly walled boxes, have a more modest distance across sharp edges than a normal nail. Completing nail have a tiny breadth knife to make the littlest opening conceivable.

The most commonplace nail point is a four-sided tightened cut called a jewel point. The different nail might have a blunter highlight feature dividing specific woods. Focuses, thorned focuses, needle focuses, and numerous others are now and again utilized on strong nail.

Read more: ALL ABOUT NAILS

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.