Blog

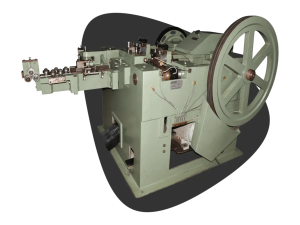

Grooving Nail Machine

Looking to boost your nail production efficiency? Discover our Grooving Nail Machines at Gujarat Wire Products. Choose between High-Speed and Wire Nail Making Machines to optimize your output, enhance product quality, and streamline your manufacturing process. Visit us today to transform your production line!

Unlock the Potential of Grooving Nail Machines for Efficient Manufacturing

In today’s competitive market, efficiency in manufacturing is paramount. For industries that rely on fast and reliable nail production, investing in a high-quality grooving nail machine is a game changer. At Gujarat Wire Products, we specialize in two types of grooving nail machines that stand out for their speed and performance.

Introduction to Grooving Nail Machines

A grooving nail machine is vital for producing grooved nails used in various construction and woodworking projects. These nails ensure better grip and load distribution when driven into materials. Understanding the different types available is crucial for selecting the right machine for your needs.

Types of Grooving Nail Machines

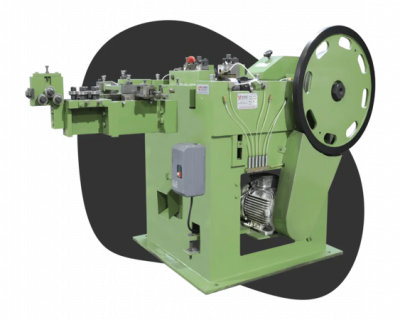

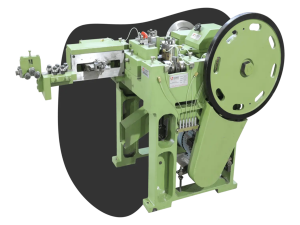

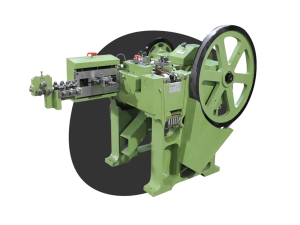

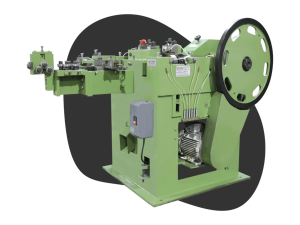

High-Speed Nail Making Machine

Designed for mass production, this machine operates at an impressive speed, significantly cutting down manufacturing time. Its robust construction ensures longevity and minimal maintenance, making it a cost-effective solution for large-scale operations.

|  |  |

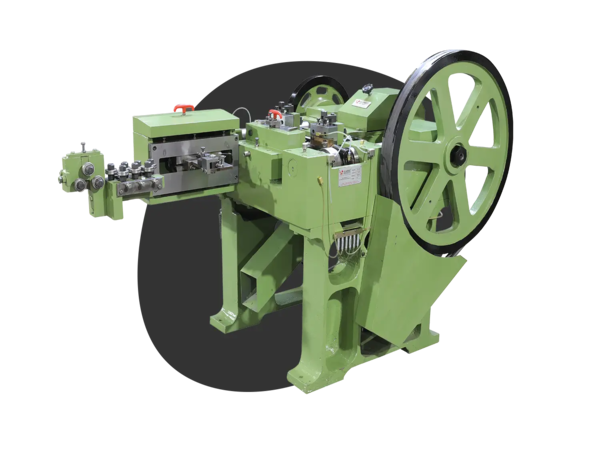

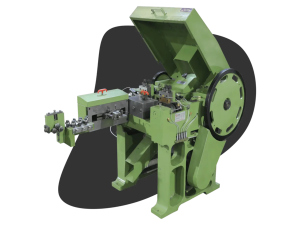

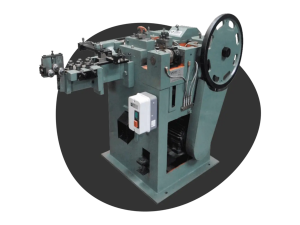

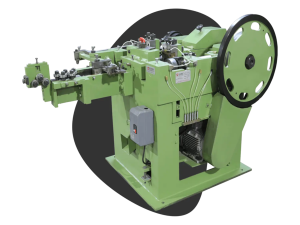

Wire Nail Making Machine

This versatile machine caters to a range of nail sizes, offering flexibility for manufacturers who deal with diverse product lines. The precision engineering behind this machine allows for consistent quality and reliability in nail production.

|  |  |

|  |

Benefits of Using Grooving Nail Machines

- Increased Productivity: Both types of machines maximize output, ensuring that your production lines are as efficient as possible.

- Versatility: With capabilities to produce a variety of nail sizes, these machines serve multiple markets, enhancing your product offerings.

- Cost Efficiency: Reduced labor costs and increased production speed result in a higher return on investment.

- Quality Assurance: Consistent nail quality reduces waste and increases customer satisfaction.

Choosing the Right Machine

Selecting the right grooving nail machine depends on your production requirements. Consider the following:

- Production Volume: High-speed machines are ideal for large volumes, while wire nail machines offer flexibility for smaller, diverse batches.

- Material Compatibility: Ensure the machine can handle the specific materials and nail sizes your production requires.

- Maintenance and Support: Opt for machines that offer easy maintenance and accessible customer support.

Innovation in Nail Manufacturing

At Gujarat Wire Products, innovation is at the core of what we do. Our machines are not only built to last but are also equipped with advanced features that set them apart from conventional nail making machines. This includes enhanced safety features, energy efficiency, and user-friendly controls.

Future of Nail Manufacturing

The future of nail manufacturing lies in automation and integration with IoT technology, enabling smarter production processes and real-time monitoring. Staying ahead of these trends is crucial for maintaining competitiveness in the industry.

Conclusion

Grooving nail machines are indispensable for manufacturers looking to improve efficiency and product quality. By choosing the right machine, you can significantly enhance your production capabilities and market position.

Contact information and how to order

To order Grooving Nail Machines from Gujarat Wire Products, you can contact us through the following channels:

– Phone: +91-9824456375

– Email: info@gujaratwireproducts.com

– Website: www.gujaratwireproducts.com/contact-us

Read About: Clout Nail Making Machine Manufacturer

Please visit our official Facebook Page for updates from us.