Blog

1 To 4 Inch Wire Nail Machine

Discover the best 1 to 4 Inch Wire Nail Machines at Gujarat Wire Products. We offer both standard and high-speed machines designed for precision, durability, and efficiency. Perfect for various industrial applications, our machines ensure high-quality nail production to meet your business needs. Contact us today!

Discover Our Advanced 1 to 4 Inch Wire Nail Machines

Wire nails play a crucial role in construction and various industrial applications. At Gujarat Wire Products, we specialize in manufacturing top-quality 1 to 4 Inch Wire Nail Machines. Our machines are designed to deliver high performance, precision, and durability. In this blog, we’ll explore the different types of wire nail machines we offer and their unique features.

The Importance of Quality Wire Nail Machines

High-quality wire nails are essential for ensuring the structural integrity of buildings and other constructions. The performance of wire nail machines directly impacts the quality of the nails produced. At Gujarat Wire Products, we understand this importance. Our wire nail machines are built to meet the highest standards of quality and efficiency.

Types of 1 to 4 Inch Wire Nail Machines

We offer two primary types of wire nail machines: Wire Nail Making Machines and High-Speed Wire Nail Making Machines. Let’s dive into the specifics of each type.

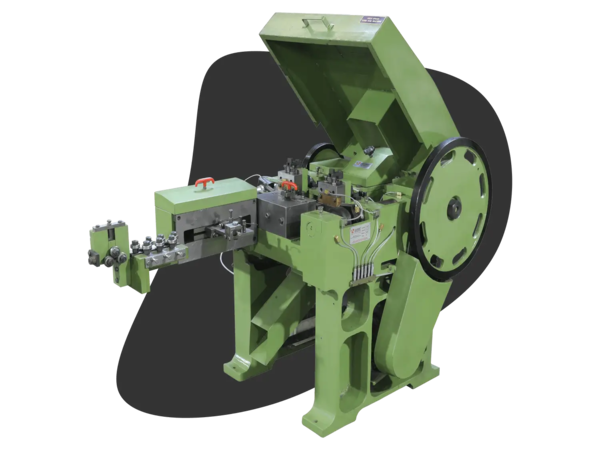

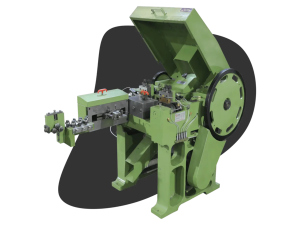

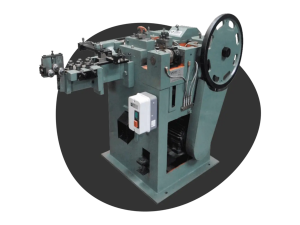

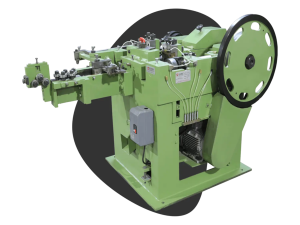

High-Speed Nail Making Machine: Efficiency at Its Best

For businesses that require higher production speeds, our High-Speed Wire Nail Making Machines are the perfect solution. These machines are engineered to produce nails at a faster rate without compromising on quality. They are suitable for large-scale production environments.

|  |  |

Key Features of High-Speed Wire Nail Making Machines

- Increased Production Speed: Significantly reduces production time.

- Consistent Quality: Maintains high standards for each nail produced.

- Energy Efficient: Designed to consume less power while delivering high performance.

- Low Maintenance: Requires minimal upkeep, reducing downtime.

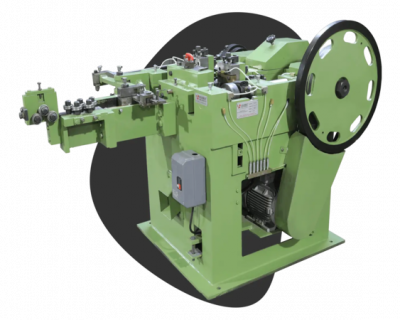

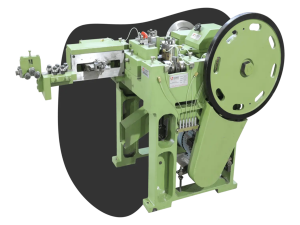

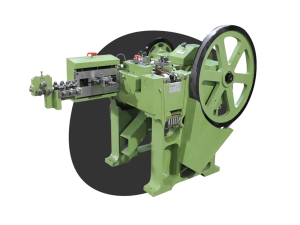

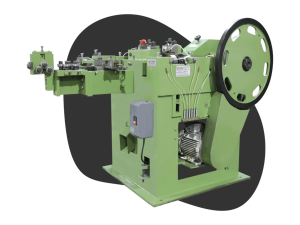

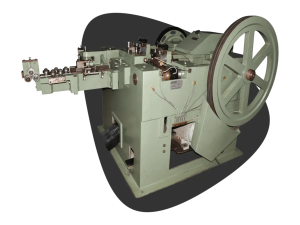

Wire Nail Making Machine: Versatility Meets Durability

Our Wire Nail Making Machines are designed for precision and reliability. They are perfect for producing standard wire nails in various sizes ranging from 1 to 4 inches. These machines are robust and user-friendly, making them ideal for small to medium-scale production.

|  |  |

|  |

Key Features of Wire Nail Making Machines

- High Precision: Ensures accurate nail length and diameter.

- Durability: Built with high-quality materials for long-lasting performance.

- User-Friendly Design: Easy to operate and maintain.

- Versatility: Capable of producing nails in multiple sizes.

Why Choose Gujarat Wire Products?

Gujarat Wire Products is committed to delivering excellence in every machine we manufacture. Here are some reasons why you should choose our wire nail machines:

- Innovation: We continuously improve our machines to incorporate the latest technology.

- Quality Assurance: Each machine undergoes rigorous testing to ensure it meets our high standards.

- Customer Support: Our dedicated team is always ready to assist with any queries or issues.

- Customization: We offer customization options to meet specific production needs.

Applications of 1 to 4 Inch Wire Nails

Wire nails produced by our machines are used in various applications. These include construction, furniture making, and general manufacturing. The versatility of wire nails makes them a staple in many industries.

Maintaining Your Wire Nail Machines

Proper maintenance of wire nail machines is essential to ensure their longevity and performance. Regular lubrication, timely replacement of worn-out parts, and thorough cleaning are some of the maintenance practices we recommend.

Conclusion

Investing in high-quality wire nail machines from Gujarat Wire Products is a smart choice for any business. Our machines are designed to deliver exceptional performance, durability, and efficiency. Whether you need standard or high-speed wire nail making machines, we have the right solution for you.

Contact Us today to learn more about our 1 to 4 Inch Wire Nail Machines and how they can benefit your business. Let us help you take your production capabilities to the next level.

Contact information and how to order

To order 1 To 4 Inch Wire Nail Machines from Gujarat Wire Products, you can contact us through the following channels:

– Phone: +91-9824456375

– Email: info@gujaratwireproducts.com

– Website: www.gujaratwireproducts.com/contact-us

Read About: Clout Nail Making Machine

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.