Blog

All about Wire Nails Making Machine Sharpening Dies

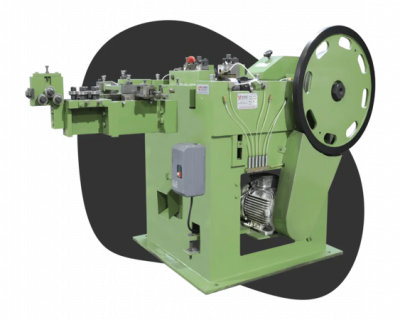

The Wire Nails Making Machine sharpens the top of the steel wire before inserting it into the wire drawing machine. The drawing machine employs various heights and widths of drawing dies for the process.

Nail blade grinder:

After 1–2 days of cutting, the nail sharpening edge set up on the wire nail-making machines will become blunt, then, you can utilize the nail sharpening grinder to crush the nail sharpening edge to make it sharper.

Grasping Dies:

The machines use round dies with grooves that hold 8 or 10 nails.

Cutting Die:

By properly crushing the tools, one can generate Diamond, Chisel, Round, Long, or blunt-formed points for cutting nails and shaping them after framing the top and knife.

Header Dies:

These dies can shape nail tops, whether they are Chequered or Plain, by utilizing them.

Nail Cutter and Die Grinder (provided with an engine)

Discretionary Accessories:

Additional arrangements of Tooling such as a Set of Gripping Dies, Cutting Tools, and Header Dies

Standard Accessories:

Electric Motor, Starter, Belts, One bunch of Tooling, Wire Stand and Hand Operated Lubrication Pump.

Read more: Drive Nails into Concrete

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.