Blog

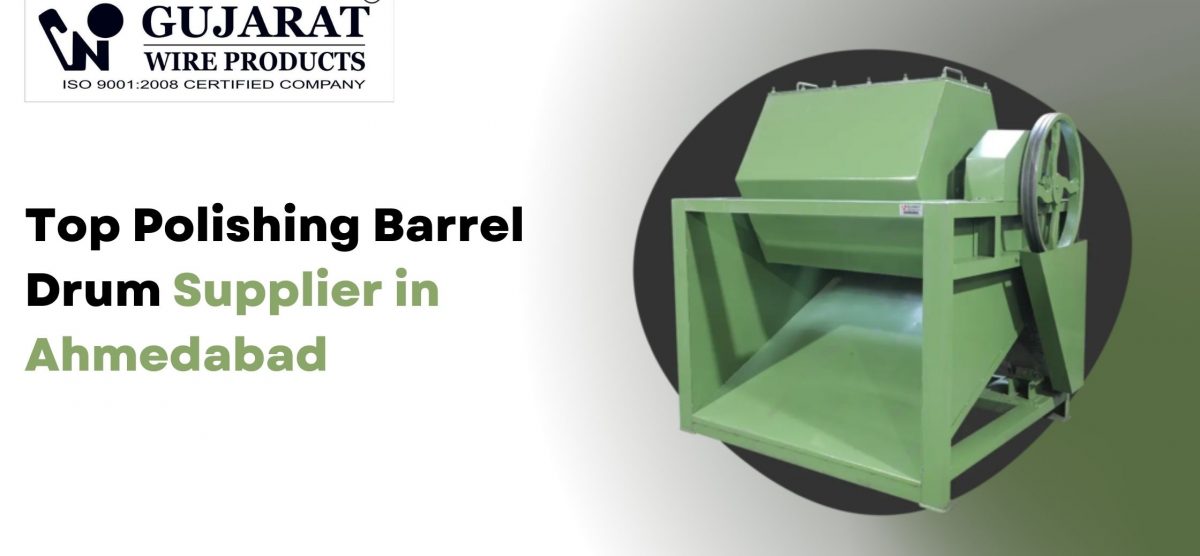

Top Polishing Barrel Drum Supplier in Ahmedabad

Introduction

Surface finishing often becomes a silent bottleneck. Parts look acceptable at first glance, yet small burrs, uneven shine, or inconsistent edges slow down inspection, packing, and dispatch. Many manufacturers in Ahmedabad still rely on manual polishing or undersized tumbling setups that cannot keep pace with batch volume. The result is uneven quality and unpredictable cycle times.

Polishing barrel drums solve this problem at the process level. They standardize surface finishing across batches, reduce operator dependency, and make output predictable. When sized and built correctly, they turn polishing from a daily firefight into a controlled, repeatable operation.

This article explains what polishing barrel drums are, how they work, and where they are used across industries in and around Ahmedabad. It also covers key features, drum types, and supplier selection criteria that directly affect finish quality and machine life. The goal is practical clarity—so buyers choose equipment that fits real production loads, not just catalog specifications.

What is a polishing barrel drum

A polishing barrel drum is a rotating container used to finish parts through tumbling action. Components are mixed with abrasive or polishing media and rotated for a set duration.

As the drum turns, friction between parts and media removes burrs, smooths edges, and improves surface finish. The process works on metal, stone, glass, and select plastic components.

Barrel drums are batch-based machines. Their strength lies in uniform results across large quantities, not one-off precision finishing.

How polishing barrel drums work

Loading and media ratio

Parts are loaded into the drum along with polishing media and, in some cases, liquid compounds. The ratio between parts and media determines finish quality.

Overloading reduces movement. Underloading increases impact damage. Correct ratios matter more than rotation speed.

Tumbling and finishing stages

As the drum rotates, parts slide and roll against the media. This controlled abrasion removes surface defects over time.

Different finishes require different cycle times. Deburring may take minutes, while high-gloss polishing can take hours.

Speed, time, and control

Rotation speed controls impact intensity. Time controls finish depth. Stable speed control prevents over-polishing and part deformation.

Most quality issues trace back to inconsistent speed or poor drum balance.

Key features and technical specifications

Capacity and batch size

Common industrial drums range from small batches to several hundred kilograms. Buyers often choose larger drums “for safety,” then run them half full.

In practice, matching drum capacity to daily batch size delivers better consistency and lower energy waste.

Drum material and lining

Mild steel drums are widely used for general applications. Stainless steel drums suit corrosive environments or wet polishing.

Internal linings reduce noise and protect delicate parts. This feature often extends part quality more than media changes.

Motor and drive system

Stable torque matters more than peak power. Smooth rotation under load prevents sudden impacts that cause surface dents.

Gear-driven systems usually outperform belt-only setups in long-term stability.

Customization options

Custom drum size, tilt angle, discharge method, and control panels improve workflow fit. These changes often save more time than increasing speed.

Types of polishing barrel drums

Mild steel and stainless steel drums

Mild steel suits dry polishing and heavy-duty use. Stainless steel is preferred for wet processes and contamination-sensitive parts.

Material choice affects cleaning effort and media life.

Manual and semi-automatic drums

Manual drums require operator intervention for loading and unloading. Semi-automatic drums reduce handling time and improve safety.

For repetitive batches, semi-automatic setups usually justify themselves quickly.

Fixed and tilt-rotary drums

Fixed drums suit simple processes. Tilt-rotary drums simplify discharge and reduce operator strain.

Plants with frequent batch changes benefit most from tilt designs.

Industrial use cases

Wire nail and fastener finishing

Barrel drums remove sharp edges and improve surface appearance. Uniform tumbling prevents nail bending and head damage.

This step often reduces packing injuries and customer complaints.

Hardware and machined components

Bolts, washers, and small machined parts benefit from consistent edge rounding. Manual polishing rarely achieves this at scale.

Jewelry and precision parts

Fine parts require controlled media and lower speeds. Wet polishing drums dominate this segment.

Surface defects here are visible immediately, making process control critical.

Automotive and general engineering

High-volume components need predictable cycle times. Barrel drums allow parallel processing without line congestion.

Stone and glass tumbling

Drums smooth edges and improve finish on decorative components. Long cycle stability matters more than speed.

Benefits and business value

Polishing barrel drums deliver value beyond surface appearance.

- Uniform finish across batches

- Reduced manual labor and fatigue

- Lower rework and inspection time

- Predictable cycle scheduling

- Safer handling of finished parts

A less discussed benefit is planning confidence. When polishing becomes predictable, downstream packing and dispatch stabilize automatically.

How to choose the right supplier in Ahmedabad

Match capacity to real throughput

Suppliers often promote maximum load. Buyers should calculate average daily batch size instead.

Oversized drums waste energy and space while underperforming on consistency.

Evaluate build quality and balance

Poorly balanced drums cause vibration, noise, and uneven finish. Structural rigidity matters more than cosmetic design.

Check service access and spares

Downtime often comes from small parts—bearings, seals, belts. Local support reduces stoppage duration.

Look for application understanding

Suppliers who ask about part geometry, material, and finish expectations usually deliver better long-term results.

Comparison of models and specifications

Across workshops, a clear pattern appears. Medium-capacity drums running consistently outperform oversized drums run cautiously.

Another uncomfortable insight is that many finish defects blamed on media are actually caused by poor drum geometry or speed instability. Hardware choices often matter more than consumables.

Conclusion

Polishing barrel drums are not optional accessories. They define finish quality, operator workload, and production flow. The right drum simplifies finishing into a controlled step. The wrong one becomes a hidden bottleneck.

If you are sourcing a polishing barrel drum in Ahmedabad, focus on capacity fit, mechanical balance, and service support—not just price or size.

Gujarat Wire Products supplies polishing barrel drums engineered for consistent finishing, stable operation, and long service life. We work with manufacturers to match drum design to actual batch loads and surface requirements.

Take the next step. Contact Gujarat Wire Products to discuss your finishing process and receive a recommendation built around your production reality.