Blog

Choosing High Speed Nail Making Machine Types

The nail making machine sitting on your factory floor determines whether you dominate regional supply contracts or lose margin to faster competitors. Here’s what most buyers get wrong: they prioritize speed ratings over changeover flexibility. A machine advertised at 800 nails per minute means nothing if switching from 2-inch to 4-inch nails takes 90 minutes and requires two technicians. High-speed nail production depends on matching machine type to your actual order mix, not chasing maximum theoretical output. Buyers who ignore this end up with expensive equipment that runs at 60% capacity because their product mix doesn’t align with the machine’s design strengths. This guide breaks down the four main high-speed machine types, the technical features that actually matter, how speed ratings deceive buyers, and the decision framework that prevents costly mismatches between equipment capabilities and real production demands.

Machine Types and Their Real Strengths

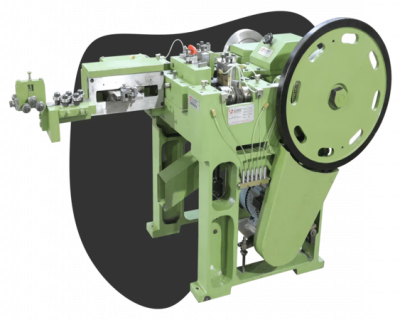

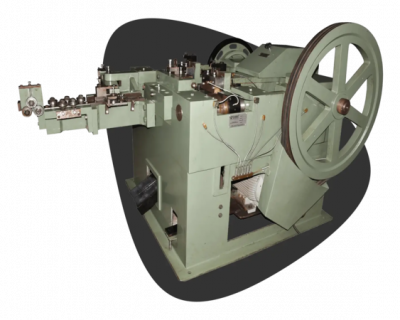

Fully Automatic Wire Nail Machines

These systems handle the complete production cycle from wire feeding through point shaping without manual intervention. They excel at high-volume production of common wire nails used in construction—typically 2-inch to 6-inch lengths. Production speeds range from 300 to 600 nails per minute depending on wire diameter and nail length.

The hidden limitation: fully automatic machines struggle with frequent size changes. Die replacement and calibration for different nail specifications can consume 60-90 minutes per changeover. This makes them ideal for manufacturers running large batches of identical specifications but inefficient for operations serving diverse customer requirements.

Umbrella Head Nail Machines

Specialized equipment designed for roofing nails with broad, flat heads that seal against sheet metal and roofing materials. These machines form the distinctive wide cap through secondary pressing operations after initial nail formation. Production speeds typically reach 400-500 nails per minute.

Umbrella head machines represent a classic example of specialization over versatility. They cannot produce standard wire nails efficiently. Buyers serving roofing contractors need dedicated umbrella head equipment, while general fastener manufacturers should avoid them entirely.

High-Speed Precision Machines

Built around advanced cam systems and servo motors, these machines prioritize dimensional consistency at elevated speeds. They maintain tolerances within ±0.1mm across nail length and diameter while producing 600-800 nails per minute. PLC controls monitor die wear and automatically adjust cutting parameters to compensate.

The cost trade-off is significant—precision high-speed machines command 40-60% price premiums over standard automatic models. This investment only makes sense when serving customers with strict quality specifications or producing specialty nails where defect rates above 1% trigger contract penalties.

Custom Application Machines

These systems produce specialized nail types including twisted shank nails for flooring, ring shank nails for holding power, and grooved nails for masonry applications. Custom machines incorporate additional forming stations beyond standard cut-and-head operations. Production speeds drop to 200-400 nails per minute due to complex forming sequences.

Custom machines rarely appear in buyer research, yet they unlock niche markets with 30-50% higher selling prices compared to commodity wire nails. Manufacturers avoiding commodity competition should explore custom equipment despite lower output speeds.

Speed Ratings That Mislead Buyers

Machine specifications list maximum production speeds under ideal conditions: optimal wire diameter, perfect material hardness, and zero stoppages. Real-world production achieves 65-75% of rated speeds once you account for wire breaks, die changes, and material inconsistencies.

A machine rated at 800 nails per minute will deliver 520-600 nails per minute in actual operations. Buyers who calculate ROI using manufacturer speed claims face reality gaps of 25-35% between projected and actual output. Always reduce advertised speeds by 25% when modeling production capacity.

Critical Technical Features

Changeover Speed Design

Quick-change die systems reduce specification switching from 90 minutes to 15-20 minutes. This matters enormously for operations producing multiple nail sizes. Machines with tool-free die positioning and calibrated die sets enable single-operator changeovers versus two-person teams required by older designs.

Changeover capability adds 20-30% to equipment cost but increases daily production by allowing more efficient batch scheduling and smaller inventory holdings.

Vibration Control and Frame Rigidity

High-speed operations generate significant vibration that causes die misalignment and dimensional drift. Heavy cast frames and isolated mounting systems maintain precision during extended production runs. Lightweight frames save initial cost but require frequent recalibration and produce higher defect rates.

Frame quality directly determines whether machines maintain specifications across 16-hour shifts or need operator intervention every 2-3 hours.

Wire Feeding Consistency

Synchronized feeding systems prevent wire slippage that causes length variations and incomplete nail formation. Variable frequency drives adjust motor speed based on real-time tension feedback. Older fixed-speed systems cannot compensate for wire hardness variations between material batches, resulting in 5-8% defect rates versus 1-2% with adaptive feeding.

The Decision Framework

Match machine type to your top three nail specifications by volume. Don’t optimize for occasional specialty orders. Calculate changeover time cost against batch size flexibility. Operations producing 10+ nail sizes daily need quick-change systems regardless of price premiums. Manufacturers running week-long batches of identical specs maximize ROI with basic automatic machines.

Verify power supply capacity. High-speed machines draw 15-25kW during operation. Factory electrical systems often require upgrades to support advanced equipment.

FAQs

Q: How long does changeover between nail sizes actually take?

A: Standard machines require 60-90 minutes with two operators. Quick-change systems reduce this to 15-20 minutes with one operator. Calculate changeover frequency to determine if premium quick-change design justifies 25-30% higher cost.

Q: Can one machine handle both wire nails and specialty types?

A: No. Umbrella head, twisted shank, and ring shank nails require dedicated equipment with specialized forming stations. Attempting specialty production on wire nail machines produces 20-30% defect rates and excessive die wear.

Q: What maintenance frequency do high-speed machines require?

A: Daily lubrication checks, weekly die inspections, monthly calibration reviews. Die replacement every 500,000 cycles maintains dimensional accuracy. Operators need structured training—untrained personnel cause wire breakage rates exceeding 8% versus 2% with proper operation knowledge.

Q: Do speed ratings reflect real production conditions?

A: No. Manufacturer specifications show maximum output under ideal conditions. Reduce advertised speeds by 25% to estimate actual production accounting for wire breaks, material variations, and routine stoppages.

Conclusion

High-speed nail machine selection hinges on matching equipment capabilities to actual order patterns, not chasing maximum speed specifications. The right machine type aligned with real production demands outperforms faster equipment poorly matched to operational needs.

Gujarat Wire Products engineers nail making systems built around real manufacturing conditions, not laboratory specifications. Our equipment delivers consistent output across extended production cycles while accommodating the size flexibility Indian manufacturers actually need. Ready to match machine capabilities to your production reality? Visitgujaratwireproducts.com or contact our application engineering team for a production analysis and equipment recommendation based on your specific order mix.