Blog

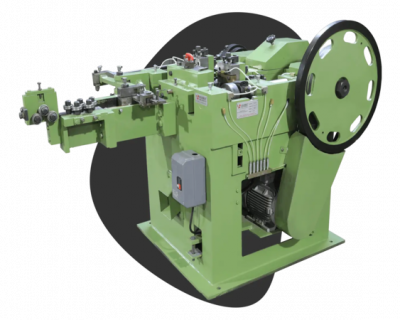

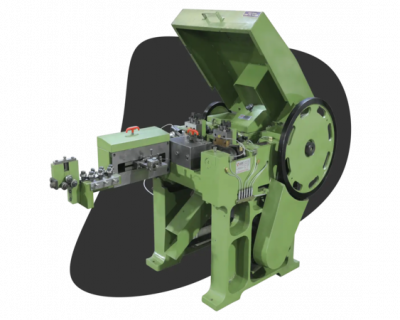

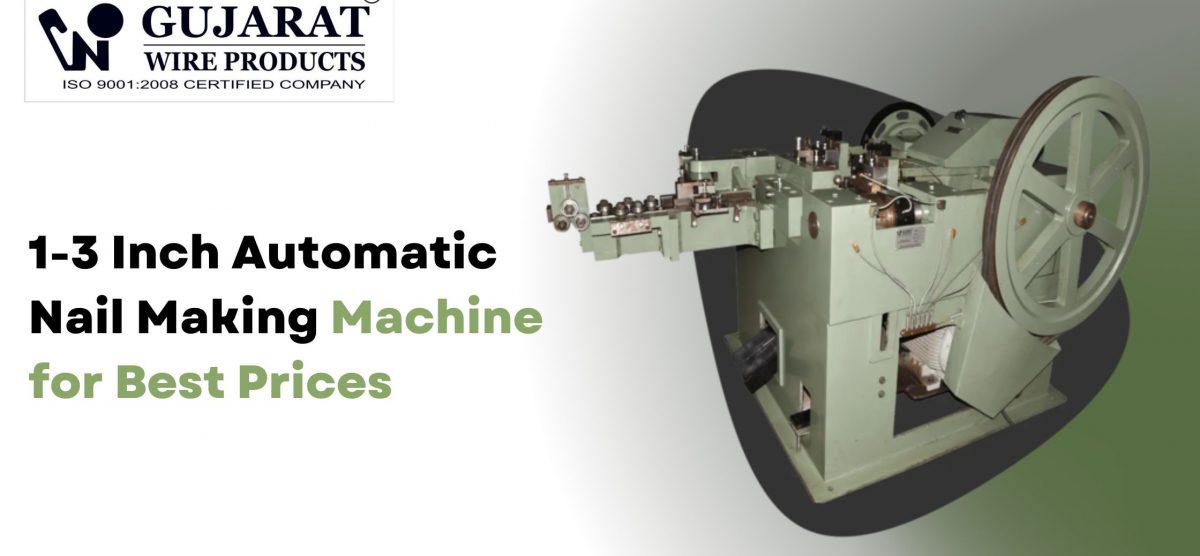

1-3 Inch Automatic Nail Making Machine for Best Prices

Introduction

Construction projects stall when nail supply runs out. Furniture manufacturers lose contracts when production can’t scale. And small-scale manufacturers watch profits evaporate because manual labor costs keep climbing. The 1-3 inch nail segment sits right in the sweet spot of industrial demand—common enough to guarantee steady sales, specialized enough to command better margins than commodity sizes. But here’s what most buyers miss: the machine price matters far less than what it costs you not to have one. An automatic nail making machine in this size range transforms your operation from labor-dependent to capacity-driven. It turns you from a nail buyer into a nail supplier.

This guide details specifications, costs, and benefits to help buyers choose a nail-making machine that runs longer and earns them more.

Product Specifications

Motor Power and Production Capacity

Most 1-3 inch machines run on 3-5 HP motors and produce between 300 to 500 nails per minute. That translates to roughly 800-1,200 kg of finished nails per eight-hour shift. The market data shows machines achieving up to 760 pieces per minute with zero defective output. Wire diameter compatibility typically ranges from 1.9mm to 2.5mm, accommodating standard MS wire that’s available at bulk rates across India.

Machine Construction and Durability

Industrial-grade machines weigh between 1,140 kg to 2,800 kg, built with steel frames designed for continuous operation. The heavier construction dampens vibration and maintains alignment during high-speed production. Voltage requirements stay standard at 320-440V, matching existing factory infrastructure without special electrical work.

Cost Structure and ROI

Initial Investment vs. Operating Costs

Here’s where the math gets interesting. Automated nail making systems cut manual labor requirements by 60-70% compared to traditional setups. One operator can manage up to 10 machines simultaneously. Monthly revenue potential ranges from ₹14,00,000 to ₹22,00,000 based on local market rates and production volume. Raw material costs stay predictable when buying wire in bulk.

Breakeven Timeline

Most operations hit breakeven within 8 to 14 months, with annual ROI between 80-120%. The fully automatic nail making machine market itself is expanding at 6.1% CAGR, growing from USD 285.4 million in 2025 to USD 516 million by 2035. That growth signals sustained demand and pricing stability.

Operational Advantages

Labor Cost Reduction

The single biggest advantage isn’t speed—it’s consistency. Modern machines produce zero defective nails, eliminating the downstream costs of sorting, rework, and customer complaints. Labor cost reduction hits 50-70% on nail making and another 35-45% on nail coiling because there are no defective pieces breaking the process. Clean, low-noise production also means you can operate in mixed-use industrial areas without permit complications.

Scalability and Market Positioning

Automatic capacity creates leverage for larger contracts. Construction suppliers need reliable volume commitments. With manual production, you’re always one worker shortage away from missing deadlines. With automated machines, your capacity becomes predictable. That predictability lets you bid on jobs competitors can’t touch.

Technical Features

Wire Feeding and Nail Forming

Automatic wire feeding eliminates manual loading between production runs. The nail head forming process happens in a single strike, maintaining uniform dimensions across thousands of pieces. Speed adjustability lets you optimize for different wire grades without extensive retooling.

Maintenance and Longevity

Regular maintenance keeps machines running for decades, not years. The key cost advantage isn’t in the machine price—it’s in the production cost savings that compound month after month. Producing one ton of nails costs roughly $20 less with automated equipment compared to manual methods.

Selection Criteria

Matching Capacity to Demand

Don’t buy capacity you can’t fill. Start by mapping your current nail consumption or target customer demand. If local construction activity drives 15,000 kg monthly demand and you can capture 20% market share, that’s 3,000 kg you need to produce. Work backward from that number to determine shift requirements and machine specifications.

Quality Standards and Support

Look for machines that deliver consistent nail dimensions without constant adjustment. The difference between a good machine and a mediocre one shows up in downtime hours, not spec sheets. Local technical support matters more than marginally higher production speeds.

FAQs

Q: What wire gauge works best for 1-3 inch nails?

A: Standard 1-3 inch nails use 10-17 gauge wire, with thicker gauges for construction applications and thinner ones for finishing work. Most machines handle this range without tooling changes.

Q: How much floor space does installation require?

A: Plan for roughly 1,600mm x 1,550mm x 1,000mm for the machine itself, plus workspace for wire spools and finished nail collection. Total footprint runs about 200-250 square feet including operator access.

Q: Can one machine produce multiple nail sizes?

A: Yes. Length adjustment happens on the machine through simple controls. Diameter changes require matching wire thickness to your target nail specification.

Q: What’s the typical power consumption per shift?

A: A 3-5 HP motor running eight hours consumes approximately 18-30 kWh depending on load and efficiency. Calculate based on your local industrial electricity rates for accurate cost projections.

Q: How long does operator training take?

A: Most operators become proficient within 3-5 days of supervised operation. The learning curve is short because modern machines automate the complex adjustments.

Conclusion

The decision to invest in a 1-3 inch automatic nail making machine comes down to one question: do the economics support your growth plans? If manual labor costs keep rising, if customer demand exceeds current capacity, or if you’re buying nails at retail to fulfill orders—the machine pays for itself. Contact us today for a custom ROI calculation based on your specific production requirements.

Gujarat Wire Products has manufactured precision nail making machines since 1975, serving manufacturers across India, Africa, Europe, and Asia. Our ISO 9001:2008 certified machines combine proven mechanical design with modern automation, delivering consistent output in real-world industrial conditions. We provide complete technical support, operator training, and spare parts availability that keeps your production running.

Get your custom quote today—reach out through our website at gujaratwireproducts.com or call our technical team to discuss your production goals.