Blog

Top Wire Nail Cutting Tools Supplier in India

Wire nails are foundational fasteners across construction, furniture, packaging, and countless other industries. At the heart of every reliable wire nail is a seamless production process—powered by advanced machinery and, critically, by precision-engineered wire nail cutting tools. In India’s fast-growing wire nail sector, where efficiency, durability, and surface finish are paramount, the quality of cutting tools determines not just output, but the consistency and reputation of every finished nail.

Gujarat Wire Products is renowned as the top wire nail cutting tools supplier in India. This reputation has been hard-earned, built on decades of innovation, stringent quality control, and technical expertise. This blog explores why wire nail cutting tools matter, what makes Gujarat Wire Products an industry leader, and how investing in the right tools can transform your operations and profitability.

Understanding Wire Nail Cutting Tools

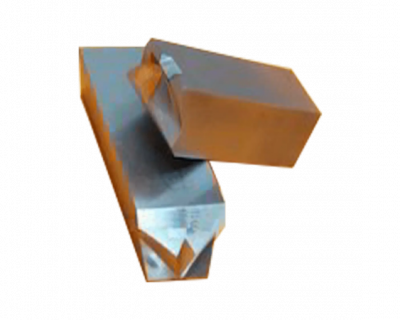

Wire nail cutting tools are specialized machine components designed to precisely shear wire into defined lengths before being formed into nails. The most common types include carbide cutters, die sets, and customized forms to handle varying wire sizes and head styles.

Functions and Importance

- Precision Cutting: Ensures nails are uniform, free of burrs or rough ends.

- Tool Longevity: High-quality cutters withstand intense operational cycles without premature wear, reducing maintenance and downtime.

- Surface Finish: The sharper and harder the cutting edge, the smoother the final nail’s surface—a key factor for markets such as furniture or export.

- Productivity: Superior tools translate to higher feed rates and more nails per shift, maximizing return on machinery investment.

Market Insights: India’s Expanding Cutting Tools Sector

India’s cutting tools market, catering to all industrial sectors including wire nail manufacturing, reached an estimated $2.96 billion in 2024 and is forecast to surpass $5.24 billion by 2033, with a CAGR of over 6%. This explosive growth is propelled by rising infrastructure projects, government-backed manufacturing initiatives, and the global shift towards ‘Make in India’.

In the wire nail subsector, experts estimate the wire nail market itself will hit ₹7,800 crore by 2025, growing at roughly 8% per annum. At the core of this expansion is the need for precision, durability, and advanced automation—all of which depend on high-quality cutting tools to achieve modern standards.

Why Cutting Tool Quality is Mission-Critical?

1. Productivity & Output

Inferior cutting tools blunt quickly, leading to frequent machine stops, defective nails, and mounting operational costs. Conversely, premium cutters like those from Gujarat Wire Products extend operational intervals, support high-speed production, and minimize unplanned downtime.

2. Nail Consistency & Surface Excellence

The specification of the cutting die directly impacts how cleanly wire is sheared, determining the uniformity and smoothness of every nail’s shank and tip. This is particularly vital for applications demanding high strength or flawless appearance—such as concrete nails or decorative joinery.

3. Reduced Scrap and Defect Rates

Precision tools lower the risk of burr formation, deformed heads, and bent shanks. The result is greater material yield and less waste—a crucial consideration in large-scale, margin-sensitive manufacturing.

What Sets Gujarat Wire Products Apart?

Decades of Expertise and Innovation

Gujarat Wire Products is a name synonymous with wire nail manufacturing excellence in India. From its earliest days, the company invested in modern manufacturing, R&D, and advanced automation. Today, it offers a comprehensive spectrum of nail plant solutions—including wire nail cutting tools, gripping dies, chequered header grinders, and complete nail machines.

State-of-the-Art Manufacturing

- Advanced CNC/VMC Technology: All cutters and dies are manufactured using the latest CNC and VMC systems, ensuring micron-level tolerances and repeatability.

- Premium Material Selection: The brand is particularly known for its use of carbide—recognized for extreme hardness (over 91.8–92.4 HRC), wear resistance, and durability under high-speed operation.

- Thorough Quality Control: Every tool is stringently tested for hardness, overall geometry, and surface finish before dispatch, ensuring end users experience maximum longevity and minimal setup issues.

Customization and Versatility

No two manufacturing lines are alike. Gujarat Wire Products tailors its tool range to each client’s unique specs—offering custom lengths (from 52mm to 166mm), bespoke tool geometries, and compliance with all major wire nail machine brands.

Customer Support and Turnkey Solutions

Beyond tools, Gujarat Wire Products supplies installation, operator training, maintenance guidance, and a robust after-sales support framework. This ensures clients of all sizes—from small startups to high-volume exporters—realize full productivity and rapid troubleshooting.

Specifications: Gujarat Wire Products Wire Nail Cutting Tools

| Parameter | Specification Range |

| Material | Carbide, high-grade tool steels |

| Hardness | 91.8–92.4 HRC (Rockwell C) |

| Length Options | 52–166 mm (customized as needed) |

| Diameter Range | 0.5–10 mm wire compatibility |

| Tolerance | Micron-level, CNC guaranteed |

| Application | All wire nail machine brands |

| Finish | Precision-ground, smooth-cut |

These specifications ensure users get tools that not only last, but deliver nails of unmatched quality and consistency.

How Gujarat Wire Products Supports Modern Nail Plants?

Diverse Cutting Tools for Every Application

- Standard Carbide Cutting Tools: For regular, high-speed nail production lines.

- Custom Die & Tooling Sets: Tailored for unique head shapes, shank styles, or clients needing proprietary designs.

- Polishing and Header Grinding Tools: Comprehensive tool solutions mean every phase—cut, head, polish—can be optimized with a single trusted supplier.

Serving the Spectrum: From Startups to Export Giants

With wire nail business setup costs in India often as low as ₹5 lakhs, new entrants proliferate. Gujarat Wire Products provides accessible, easily integrated tool options for cost-constrained ventures, while offering premium, high-output solutions for established manufacturers targeting export quality or specialty nails.

Rapid Lead Times and Reliability

In a just-in-time manufacturing era, downtime is costly. Gujarat Wire Products maintains strategic stocks for high-demand models, and delivers custom tools typically within a week. Fast logistics are matched by technical documentation and support to ensure every client maximizes tool value.

Applications and Industries Served

Gujarat Wire Products cutting tools power production lines across:

- Construction fasteners: General-purpose, roofing, and masonry nails.

- Furniture and joinery: Finer decorative and finishing nails, where clean cut and finish are essential.

- Automotive and shipping: Robust shank and specialized head nails for crates, pallets, and packaging.

- Electrical and infrastructure: Specialty nails for cable trays, mounting, and utility hardware.

- Export-quality production: Meeting stringent dimensional and surface standards for international markets.

The Science Behind Carbide: Why It Dominates Modern Cutting Tools

Carbide, as a material, offers an ideal blend of hardness, toughness, and thermal stability. This results in:

- Long-lasting sharpness: Maintains cutting edge for hundreds of thousands of actions.

- Extreme wear resistance: Survives abrasive, high-speed contact without deformation.

- Heat resilience: Retains strength at high temperatures, promoting smoother cuts and less “work hardening” of the wire.

For operators, this means fewer stoppages, less downtime, and a dramatic reduction in tool replacement expenditures.

Key Considerations When Choosing Wire Nail Cutting Tools

1. Machine Compatibility

Always ensure the tool dimensions and geometry match your specific machine make and operational parameters.

2. Wire Type and Nail Spec

Hard or specialty wires (stainless, high-tensile, coated) require elevated tool hardness and sometimes different cutting profiles.

3. Production Volume

High-volume factories benefit from ultra-hard carbide options, while low-volume producers may prefer cost-effective tool steels for initial setup or small runs.

4. Finished Nail Quality Demand

If aesthetics (surface finish, absence of burrs) or structural performance are critical, invest in the highest-specification (carbide, CNC-ground) tools available.

5. Supplier Track Record

Partners like Gujarat Wire Products, backed by ISO 9001:2008 certification and decades of customer success, deliver long-term peace of mind through both product quality and after-sales service.

Maintenance Tips to Maximize Tool Life

- Routine Cleaning: Remove wire debris and residues regularly to maintain sharpness and geometry.

- Sharpen or Replace Promptly: Monitor for dulling and swap out tools before defects or machine load increase.

- Align Properly: Ensure each tool is correctly aligned when installed—misalignment causes rapid tool/failure and uneven nail cuts.

- Lubrication: Follow recommended machine and tool lubrication guides to minimize heat buildup and friction.

- Inspection Schedule: Adopt regular, documented checks for tool wear, cracks, and chipping.

Frequently Asked Questions (FAQs)

Q1: Can Gujarat Wire Products tools be used with imported machines?

A: Yes. Their cutters and dies are compatible with all common domestic and imported wire nail machine models, with full custom fitting available on request.

Q2: How quickly can tools be delivered?

A: Many popular sizes are ready to ship. Custom options are usually fulfilled within a week for most standard applications.

Q3: Are carbide tools only for high-volume factories?

A: While preferred in high-output environments, carbide tools benefit any operation seeking high precision, reduced downtime, and premium nail finish.

Q4: Is operator training available?

A: Absolutely. Gujarat Wire Products provides operational training, troubleshooting, and maintenance guidance as part of its turnkey service offering.

Gujarat Wire Products: Empowering Indian Manufacturers for the Future

With India’s infrastructure, furniture, automotive, and export industries entering a new era of growth, the need for precision, scalability, and reliability has never been greater. Gujarat Wire Products stands at the crossroads of tradition and technological innovation—blending in-depth domain experience with a relentless drive to adopt global manufacturing standards.

Their wire nail cutting tools represent more than just accessories; they are essential engines of productivity and quality for the country’s leading manufacturers. By continually investing in advanced material science, automation, and customer-centric support, Gujarat Wire Products remains the trusted backbone of India’s wire nail industry, from Gujarat to major export hubs.

Conclusion: Make Every Nail Count with Gujarat Wire Products

In competitive manufacturing, the difference between growth and stagnation is often measured in microns—parameters determined by the quality of your cutting tools. For those who demand fast output, flawless finish, and minimal interruption, Gujarat Wire Products is the top wire nail cutting tools supplier in India. Whether you’re launching a new venture or elevating your production line for export markets, their world-class carbide cutters, tailored support, and industry-leading expertise ensure every nail not only meets but exceeds expectations.

Invest in precision. Trust in Gujarat Wire Products—India’s leader in wire nail cutting tools.