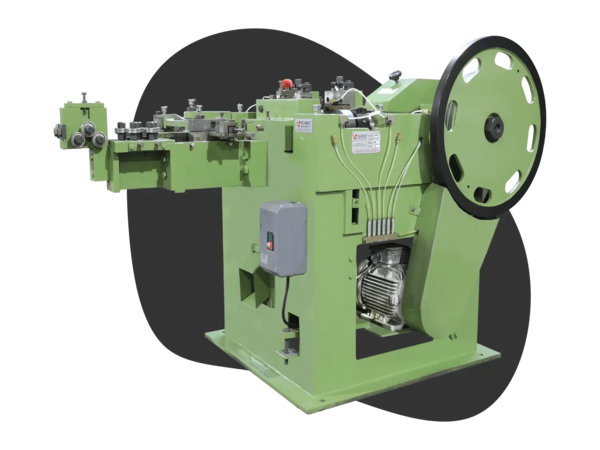

GN2

Wire Nail Making Machine

Technical Specifications

| Wire Diameter S.W.G.(mm) | 14-12 / (2-2.9) |

|---|---|

| Nail Length Inch (mm) | 1/2-2.5 / (12-65) |

| Max.Nail/min | 400 |

| Power Required hp/kw | 2 / 1.49 |

| Approx. nett Weight kgs. | 765 |

| Approx. gross Weight kgs. | 915 |

| Case Size(mm) | 1205 x 1125 x 1130 |

| Approx.Floor Area(mm) | 1375 x 950 |

The GN2 Wire Nail Making Machine is a reliable and efficient machine created for the production of wire nails. With its excellent technical specifications, this machine delivers precision and speed to the nail manufacturing industry.

The machine is capable of working with wire diameters ranging from 14 to 12 SWG (2 to 2.9 mm). This flexibility permits the production of nails with varying thicknesses, catering to different industry necessities. The nail length capacity of the GN2 Wire Nail Making Machine ranges from 1/2 to 2.5 inches (12 to 65 mm), accommodating a wide range of nail sizes.

With a maximum nail output of 400 nails per minute, the GN2 machine offers high-speed production, ensuring efficient and timely manufacturing. This capability decreases downtime and increases productivity for manufacturers.

The machine requires a power supply of 2 horsepower or 1.49 kilowatts, making it energy-efficient while providing sufficient power for a smooth process. The approximate net weight of the machine is 765 kilograms, while the gross weight is approximately 915 kilograms. These weight specifications indicate the robustness and durability of the machine.

In terms of dimensions, the GN2 Wire Nail Making Machine is designed to optimize space utilization. The case size measures 1205 x 1125 x 1130 millimetres, while the approximate floor area required for installation is 1375 x 950 millimetres. These dimensions make the machine suitable for various factory layouts, ensuring efficient use of available space.

In conclusion, the GN2 Wire Nail Making Machine is a reliable and efficient solution for nail production. Manufacturers benefit from its flexible wire diameter and nail length capabilities. It offers high production speed, a compact design, and a cost-effective option for wire nail manufacturing.