Blog

What is a Nail Making Machine & It’s Process

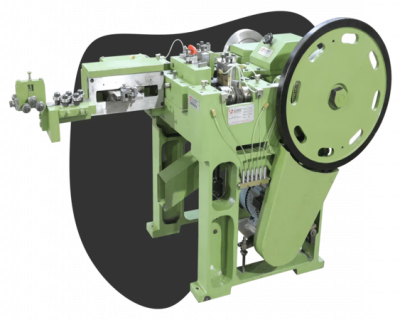

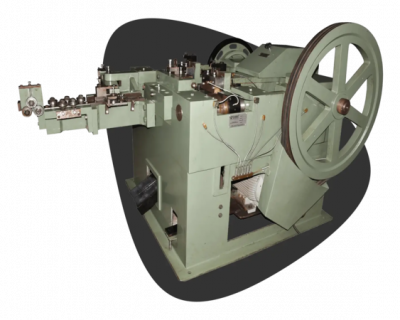

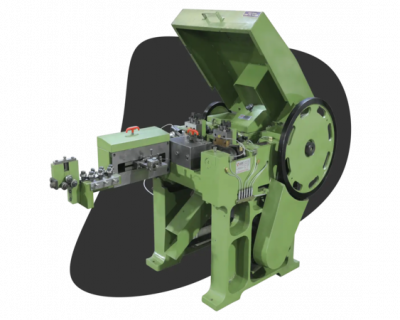

Nails Making Machine

We use the Nail Making Machine to produce various types of nails, both traditional and unique. The machine manufactures common nails, GI nails, heavy-duty nails, and curled nails. It is automatic and thus has a strong run, easy to utilize, and has large uses. Also, it comes with additional parts for elite accuracy in nail production.

The piston-type structure which the nail-making machine accepts suits its course. The design improves high velocity in nail production and buffers sound with less effect. The High-speed wire nail-making machine is kept in cyclic movement by a centralized automated lubricated framework.

In case you are into welding, the Nail Making Machine of nails is on your edge. The Nail Making Machine is able for making the highest quality oil bolt nails and a variation of molded nails that you use in nail guns just as a welding nailer.

When you purchase a steel coil and draw it to a breadth explicit to nails, the nail-making machine will do the rest for you; fixing the wire, cutting the lower part of the nail, and punching the head to frame the cap.

Recent advancements in the nail-making machine have made an in-a-machine framework. With this new qualification, the nail-making machine is equipped for making nails of determined sizes. Because of the changes begs to cut and form curled wire.

Nail Making Machine Process

Polishing barrel

The polishing barrel shines wire nails. If they become corroded, you need to add ½ litre of kerosene before adding sawdust and if not, load the polishing barrel with wire nails until it is 3 or 4 inches full. Mix the nails in with sawdust which you should add about 70% to fill the polishing barrel. You then, at that point, run the barrel for as long as 40 minutes with the visually impaired top.

When the 40 minutes pass, you need to change the lid from blind to enter. Running the barrel with the punctured lid fixed helps eliminate sawdust. In this interaction nails become brilliant. For a mirror finish, you can utilize a delicate leather piece for the polishing drum rather than sawdust.

Wire Drawing Machine

The wire drawing machine has numerous boondocks at its disposal. It can draw wires vertically and consequently. The wire drawing machine is one that shapes up nails because of its four derivatives like sturdy development, reliability, consumption obstruction, and durability.

There are two kinds of wire drawing machines;

- dry type wire drawing machine

- wet-type wire drawing machine

Read Blog: High-speed Wire Nail Making Machine

Please visit our official Facebook Page for updates from us.

For more details about our products, you can Contact Us.