Blog

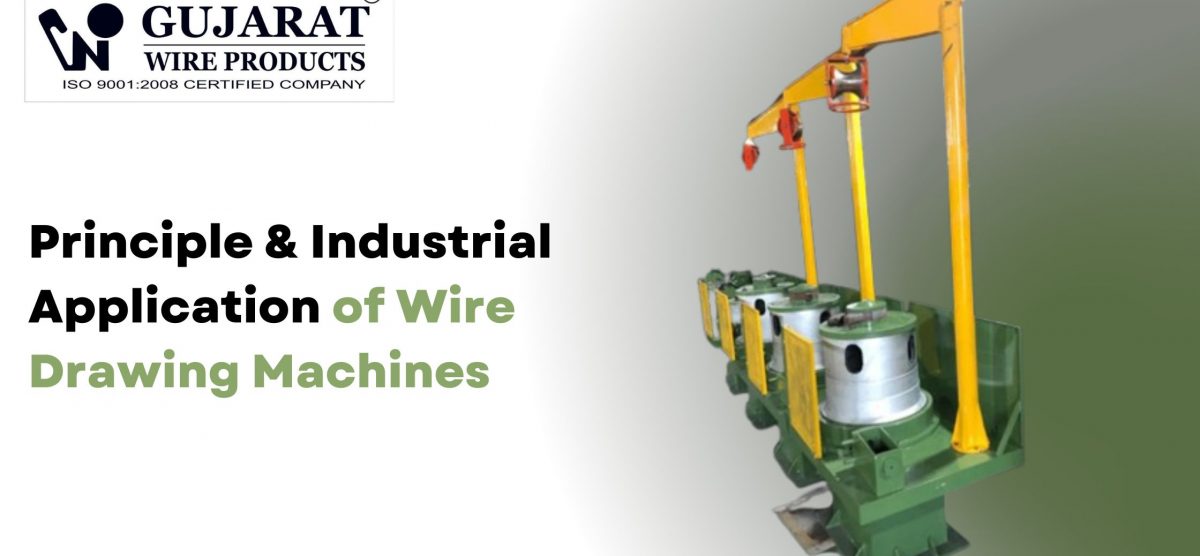

Principle & Industrial Application of Wire Drawing Machines

Introduction

Most wire manufacturers in India run their drawing machines at barely 60% capacity. That gap represents millions in lost revenue and wasted potential. Wire drawing machines transform thick metal rods into precise, thin wires through mechanical reduction—a process that powers industries from automotive to aerospace. The principle is deceptively simple: pull metal through progressively smaller dies under controlled tension. But the execution demands precision engineering, real-time monitoring, and an understanding of material behavior under stress.

This guide breaks down how wire drawing machines work, where they create the most value, and what separates efficient operations from underperforming ones. You’ll see the core components, industrial applications across sectors, and the technical factors that determine output quality. Whether you’re scaling production or entering wire manufacturing, understanding these principles is the difference between competitive pricing and margin erosion.

How Wire Drawing Works

Wire drawing relies on tensile force to reduce wire diameter. A machine pulls the metal through a hardened die, compressing its cross-section while elongating its length.

The process obeys the principle of conservation of mass. Volume remains constant as diameter shrinks and length increases. Lubrication reduces friction, preventing heat buildup and surface defects.

Multi-pass machines run wire through sequential dies, each reducing diameter by 15-25%. Single-pass reductions risk material fracture and uneven properties.

Key Components That Control Quality

Drawing Dies

Dies made from tungsten carbide or industrial diamond define final wire dimensions. Die wear directly impacts tolerance and surface finish.

Shaped dies produce non-circular profiles for specialized applications. Automotive and electronics sectors increasingly demand custom wire geometries, driving 18% growth in precision die usage since 2022.

Tension and Speed Control Systems

Constant tension prevents wire breakage and diameter variation. Modern machines use servo motors and real-time sensors to adjust pulling force across die sequences.

Drawing speeds now exceed 100 meters per minute on high-capacity lines. Speed inconsistency causes surface defects and work-hardening issues.

Lubrication and Cooling

Lubricants create a boundary layer between wire and die, reducing friction by up to 40%. Poor lubrication accelerates die wear and increases energy consumption.

Temperature control maintains material ductility. Overheating leads to grain structure changes that compromise wire strength.

Types of Wire Drawing Machines

Straight-line machines handle single-pass or limited multi-pass drawing. They suit low-volume or large-diameter wire production.

Bull block machines coil wire onto rotating drums between die stages. This configuration works for medium-diameter wires requiring multiple reductions.

Water tank systems submerge the drawing process for continuous cooling. They’re essential for high-speed copper and aluminum wire production.

Automatic straightening and cutting machines integrate post-drawing finishing. They eliminate manual handling and improve dimensional consistency.

Industrial Applications Across Sectors

Metal Wire Production

Copper, aluminum, and stainless steel wires dominate wire drawing volumes. Electrical cable manufacturing consumes 60% of global copper wire output.

Steel rope production for construction and mining requires multi-strand drawing with precise tensile properties. Spring manufacturing demands controlled work-hardening to achieve target elasticity.

Specialty and Precision Applications

Jewelry manufacturers draw gold and silver wire to sub-millimeter diameters. Consistent diameter and surface finish determine final product quality.

Aerospace and electronics sectors require wires with micron-level tolerances. These applications drive demand for diamond-die machines and real-time quality monitoring.

Plastic wire drawing produces polyester, nylon, and polypropylene filaments for textiles and industrial mesh.

Efficiency Factors and Performance Gaps

Energy-optimized wire drawing machines cut electricity costs by up to 25% compared to older models. Motor efficiency and friction reduction are the primary levers.

Material waste in wire drawing rarely exceeds 3-5% when die sequences are properly calculated. Controlled diameter reduction maximizes raw material yield.

Predictive maintenance using IoT-enabled smart dies reduces unplanned downtime by 40%. Sensor data tracks die wear patterns and lubricant performance in real-time.

Common Operational Challenges

Die wear causes diameter drift and surface imperfections. Regular inspection and replacement cycles prevent quality degradation.

Motor speed fluctuations create tension variations that lead to wire breaks. Modern drives with closed-loop feedback maintain consistent pulling force.

Insufficient lubrication raises friction, increasing energy consumption and accelerating die failure. Filtration systems remove contaminants that compromise lubricant performance.

Technology and Automation Trends

Digital integration enables real-time process monitoring across production lines. Data analytics identify efficiency bottlenecks and optimize die sequencing.

Automated die-change systems reduce transition times between wire sizes. Quick-change mechanisms cut setup time from hours to minutes.

Eco-friendly lubricants and closed-loop cooling systems reduce environmental impact. Sustainability practices now influence purchasing decisions in regulated markets.

Conclusion

Wire drawing machines convert raw metal into precision products that power modern infrastructure. The principle is mechanical reduction through dies, but efficiency depends on tension control, lubrication, die quality, and speed regulation. Industrial applications span electrical cables, automotive components, construction materials, and specialty alloys—each with distinct tolerance and surface finish requirements.

Most manufacturers underutilize their equipment capacity. Closing that gap means addressing die maintenance, optimizing lubrication systems, and implementing real-time monitoring. The difference between 60% and 90% utilization translates directly to margin improvement and competitive positioning.

Contact Gujarat Wire Products for wire drawing machines built for high-speed production and low-energy operation. Since 1975, we’ve delivered precision drawing equipment to manufacturers across India, Africa, the UK, Europe, and Asia. Our ISO 9001:2008-certified systems handle copper, aluminum, steel, and specialty alloys with consistent quality and minimal downtime. Get a production assessment and custom machine configuration for your wire manufacturing requirements athttps://gujaratwireproducts.com/.