Blog

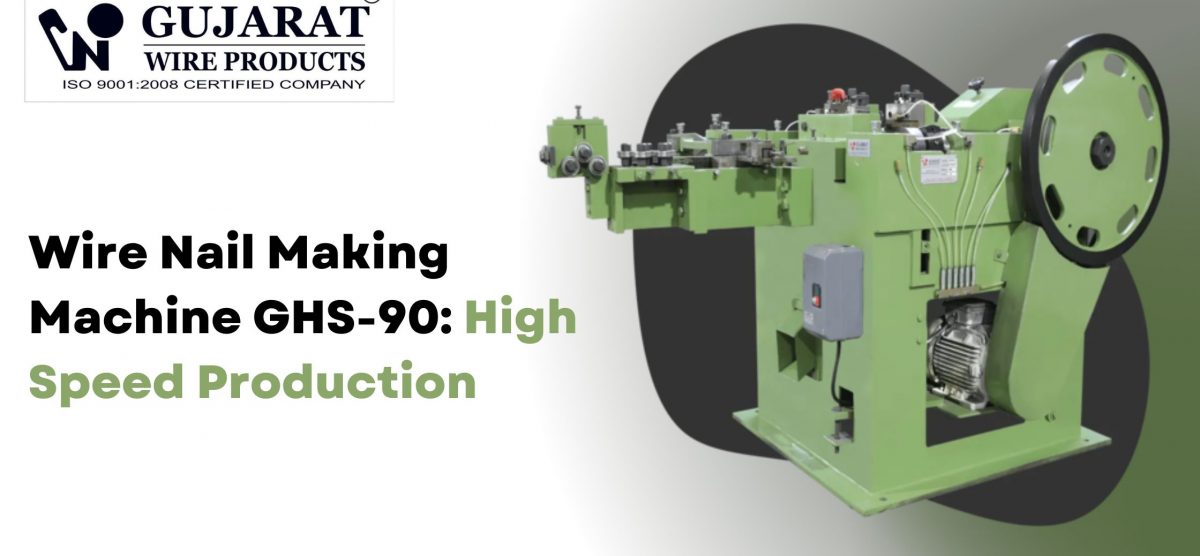

Wire Nail Making Machine GHS-90: High Speed Production

Most nail manufacturers face the same bottleneck: machines that promise speed but deliver inconsistent output, frequent breakdowns, and hidden operating costs that erode profit margins. Industry data shows that over 60% of nail production delays stem not from material shortages but from machine downtime and operator inefficiency. The GHS-90 wire nail making machine addresses this problem directly through automated high-speed production that maintains precision across extended runs.

This guide details the GHS-90’s technical features, helps evaluate high-speed production for your business, and covers maintenance for long-term profitability. Learn what makes machines productive and why speed alone doesn’t ensure lower costs.

Technical Features That Drive Performance

The GHS-90 combines specific components that directly impact output quality and consistency.

Control Systems and Automation

The machine uses a Delta PLC control system that manages wire feed, cutting, and nail ejection timing. AC drive motors provide variable speed control, letting operators adjust production rates without mechanical modifications. This matters when switching between nail sizes or materials with different forming requirements.

Safety and Monitoring Systems

Integrated sensors monitor wire tension, tool position, and nail count. These sensors halt production when parameters drift outside tolerance, preventing defective batches. Automatic lubrication systems reduce bearing wear and extend component life between service intervals.

Tooling and Durability

Tungsten carbide cutting and forming tools handle high-speed operation without frequent replacement. Tool life directly affects per-nail cost—carbide tools last 5-10 times longer than standard steel equivalents in continuous production environments.

Production Capacity and Output

The GHS-90 produces up to 500 nails per minute depending on nail length and wire diameter. This capacity suits medium to large-scale operations where consistent throughput justifies the machine investment.

Wire Diameter and Nail Size Range

The machine processes wire from 1.6mm to 5.5mm diameter and produces nails from 1 inch to 6 inches in length. This range covers common construction and industrial nail specifications without requiring multiple specialized machines.

Operator Efficiency

One trained operator can oversee two to three GHS-90 machines simultaneously. The automation level handles wire feeding, cutting, heading, and nail collection, requiring intervention only for material loading and quality spot checks. This labor efficiency distinguishes high-speed machines from older manual-feed models.

Why High Speed Production Matters

Speed alone doesn’t improve profitability. Speed combined with consistency and minimal downtime does.

Per-Unit Cost Reduction

Faster production spreads fixed costs—labor, facility overhead, machine depreciation—across more units. However, this advantage disappears if scrap rates increase or maintenance needs grow disproportionately. The GHS-90’s sensor systems maintain quality at high speed, preventing the speed-versus-quality tradeoff that plagues poorly designed machines.

Market Responsiveness

High-speed capacity lets manufacturers fulfill large orders quickly or pivot between nail specifications without production bottlenecks. This flexibility matters in markets where construction demand fluctuates seasonally or where customers require fast turnaround on custom specifications.

Choosing the Right Machine for Your Business

Not every operation needs maximum speed. Match machine capacity to actual demand patterns rather than theoretical maximums.

Production Volume Analysis

Calculate your average daily nail consumption and peak demand periods. If your consistent demand doesn’t exceed 300-400 nails per minute, a high-speed machine may sit underutilized, tying up capital without proportional returns. Machines perform best when operating at 70-85% of rated capacity—this range balances output with tool life and maintenance intervals.

Material and Specification Flexibility

Evaluate how often you switch between nail sizes and wire gauges. Machines optimized for one specification often require extensive adjustments for others. The GHS-90’s adjustable settings reduce changeover time, but operators still need training to manage transitions efficiently.

Automation Level vs. Labor Cost

Fully automated machines reduce labor needs but increase upfront costs and maintenance complexity. In regions where skilled labor is affordable and reliable, semi-automated machines may deliver better total cost of ownership. Automation makes financial sense when labor availability is limited or wage costs exceed equipment depreciation.

Maintenance Requirements

High-speed machines demand structured maintenance schedules. Neglect these and you’ll lose the speed advantage to unplanned downtime.

Daily checks include wire tension verification, tool inspection for wear or damage, and lubrication system confirmation. Weekly tasks involve cleaning debris from cutting zones and checking motor temperatures under load. Monthly maintenance includes bearing lubrication, sensor calibration, and replacement of worn consumables.

Tool replacement intervals depend on wire material hardness and production volume. Soft materials like aluminum extend tool life; high-carbon steel shortens it. Track tool performance metrics—rejection rates, surface finish quality—to establish optimal replacement schedules rather than waiting for catastrophic failure.

FAQs

What wire materials can the GHS-90 process?

The machine handles mild steel, stainless steel, aluminum, and brass wire within the specified diameter range. Harder materials require slower feed rates and more frequent tool inspection. Material hardness directly affects production speed and tool life.

How much space does the GHS-90 require?

The machine occupies approximately 1.5m x 1.2m of floor space. Plan for additional clearance around the machine for wire spool loading, maintenance access, and nail collection systems. Adequate spacing between machines improves operator efficiency and safety.

What is the typical power consumption?

The GHS-90 operates on a 7.5 HP motor drawing approximately 5.5 kW at full capacity. Actual consumption varies with production speed and material hardness. Energy costs represent 8-12% of total operating expenses in continuous production environments.

Can one machine produce multiple nail sizes simultaneously?

No. The machine produces one nail specification at a time. Changing specifications requires stopping production, adjusting wire feed and cutting parameters, and potentially replacing forming tools. Changeover takes 20-45 minutes depending on operator experience.

Conclusion

The GHS-90 delivers high-speed nail production when matched to appropriate business scale and supported by structured maintenance. Speed creates value only when combined with quality control and operational discipline. Request a production assessment to determine if high-speed automation aligns with your volume and cost structure.

Gujarat Wire Products provides complete wire nail making solutions including machine selection, installation, operator training, and ongoing technical support. We help manufacturers in Rajkot and across Gujarat optimize nail production through equipment that matches actual needs rather than maximum specifications. Our local service team ensures you maintain production efficiency long after installation.

Visitgujaratwireproducts.com or contact us directly for a consultation on the GHS-90 and other wire processing equipment tailored to your operation.