Blog

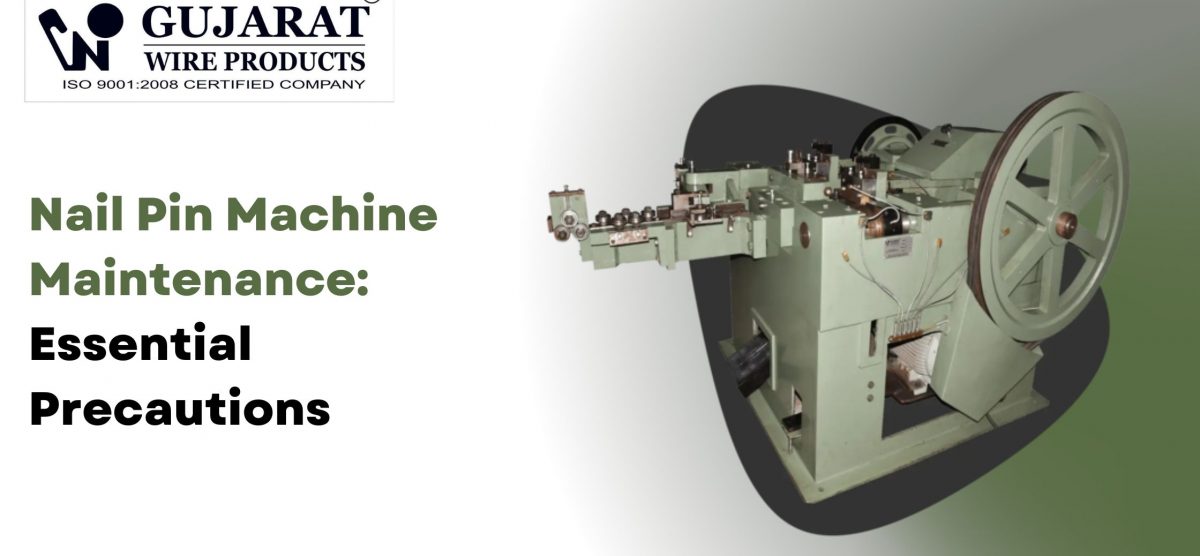

Nail Pin Machine Maintenance: Essential Precautions

Nail pin machines are the driving force behind the fastener industry, churning out millions of nails that support infrastructure, construction, packaging, and furniture manufacturing. But even the most robust nail pin machines require careful, regular maintenance to ensure efficient operation, longevity, and workplace safety. Inadequate care can lead to increased downtimes, higher repair costs, and poor product quality. At Gujarat Wire Products, we have witnessed firsthand how disciplined maintenance can be a game-changer for factory productivity and bottom-line success.

Understanding Your Nail Pin Machine: Foundations of Reliable Operation

Modern nail pin machines, including high-speed and special-shaped models, are designed with compact, plunger-based mechanisms for smoother output and lower noise. While their operation is straightforward, each run exposes internal parts to wear. Thus, ensuring optimal operating conditions and adhering to strict maintenance protocols is essential for maximizing machine life and maintaining consistent nail quality.

Essential Power and Safety Checks Before Start-up

- Power Transmission Safety: Always verify that the power switch, transmission cables, and main circuit switches meet the voltage and current demands of your nail pin machine.

- Correct Earthing: Never overlook the protection connecting wire—its cross-section must be equal to or greater than the conductor for assured safety and minimal electrical hazards.

- Pre-Operational Inspection: Before every shift, check for complete electrical integrity and ensure there are no exposed wires, loose ends, or tripped safeties.

- Lubrication Check: Confirm that the oil tank is adequately filled. Operating without proper lubrication is among the leading causes of premature machine wear.

Daily Maintenance Routine: Step-by-Step Guide

- Visual and Auditory Pre-Check

- Run the machine without load for a few minutes.

- Listen for abnormal noises and watch for unusual vibration or movement.

- Address minor issues immediately—they often signal larger problems if ignored.

- Keep It Clean and Tidy

- Remove all metal debris, dust, and oil from the machine’s exterior and working surfaces.

- Clean the nail die routinely; a clogged or dirty die diminishes nail finish and accuracy.

- Inspect and Preserve Cutting Components

- Ensure the nail knife is always sharp. Dull blades increase burrs, cause strain on the mechanism, and degrade product quality.

- Examine dies for wear, corrosion, or pitting—replace if necessary, always with original parts.

- Wire Feed Protocol

- Only use non-rusted, clean wire. Rust introduces debris and adds friction, causing pitting in finished nails.

- Begin wire feed only after the machine is running smoothly; to stop, halt the wire feed before shutting down the main mechanism.

Operating Etiquette: Actions to Avoid

- Never Adjust Machine While in Motion: Making adjustments during operation is a leading cause of misalignment, accidents, and machine damage.

- Don’t Bypass Safety Covers: Protective covers are engineered to shield operators from moving parts and debris; always replace after checks or service.

- Do Not Use Mismatched Parts: Each replacement component should match original specifications exactly to maintain tolerances and safety.

Periodic Lubrication and Inspection

- Lubricate Regularly: Schedule lubrication of all moving and friction parts, including bearings, gears, and the plunger assembly. Insufficient lubrication accelerates wear and overheating.

- Monitor Temperature: During production, routinely check the temperature of friction areas. A steady rise may signal misalignment, excessive load, or lube deficit.

- Noise Surveillance: New or increased noise often signals impending mechanical issues. Pause and inspect immediately if noticed.

Troubleshooting: Quick Reference Table

| Symptom | Possible Cause | Recommended Solution |

| Unusual machine noise/vibration | Loose bolts, worn bearings, debris | Tighten, replace, clean |

| Abnormal heating of friction parts | Insufficient lubrication, overload | Lubricate, reduce load, inspect setup |

| Damaged or misshapen nails | Dull knife, dirty die, misfeed | Sharpen/replace knife, clean die, adjust feed |

| Frequent machine stoppage | Electrical faults, motor issues | Check wiring, circuit, seek professional help |

| Oil leakage from tank/parts | Worn seals or overfilled tank | Replace seals, maintain correct oil level |

| Poor nail finish or rough edges | Rusty wire, blunt cutter, dirty mold | Use clean wire, replace cutter, clean mold |

Scheduled Shutdown and Repair Guidelines

- Power Down First: Always disconnect the power at the source before performing repairs to prevent electrical accidents.

- Scheduled Deep Cleaning: Weekly or bi-weekly, conduct a complete internal cleaning—disassemble guards, remove stuck debris from hidden spots, and inspect for worn parts.

- Parts Replacement: Use only original, high-quality replacement parts (knives, dies, belts, etc.) to retain machine accuracy and warranty compliance.

Advanced Tips for Prolonged Machine Life

- Training for Operators: Educate all operators on basic diagnostics, safe handling, and emergency stop procedures.

- Record Maintenance Activity: Keep a detailed maintenance logbook for each machine—log all lubrication, part replacements, and abnormal occurrences.

- Plan for Spare Parts: Stock vital spares (knife, die, oil, seals) to minimize unplanned downtime during emergency repairs.

- Upgrade Strategically: As technology evolves, consider periodic upgrades to more energy-efficient or automated subsystems to minimize human error and maintenance burden.

Applications and Importance in Indian Industry

Nail pin machines—especially high-speed and plunger-type models—are critical across:

- Fastener manufacturing for building and infrastructure

- Wooden furniture assembly lines

- Panel and finishing nail plants

- OEMs and construction supply specialists

Factory owners leveraging best-practice maintenance experience lower running costs, fewer stoppages, and superior nail quality that wins customers and contracts.

Frequently Asked Questions

Q: How often should I perform full maintenance?

- Visual and basic care: Daily

- Detailed lubrication and adjustments: Weekly

- In-depth inspection and cleaning: Monthly

Q: What lubricant is best for nail pin machines?

A: Use high-quality machine oil recommended by your manufacturer for optimum viscosity and wear protection.

Q: Can I use any generic replacement part for repairs?

A: No. Always use original, specification-matched parts to avoid damaging machine precision or voiding warranties.

Conclusion: Secure Your Advantage with Preventive Maintenance

Consistent, careful maintenance isn’t just about preventing breakdowns—it’s the secret to superior product quality, workforce safety, and long-term profitability. Gujarat Wire Products urges every customer to instil disciplined maintenance routines, train operators well, and invest in only genuine parts. With these precautions, your nail pin machine will deliver flawless nails, minimal waste, and smooth operation for years to come.

Protect your investment—prioritize maintenance with Gujarat Wire Products, your partner for lasting productivity in the fastener industry.