Blog

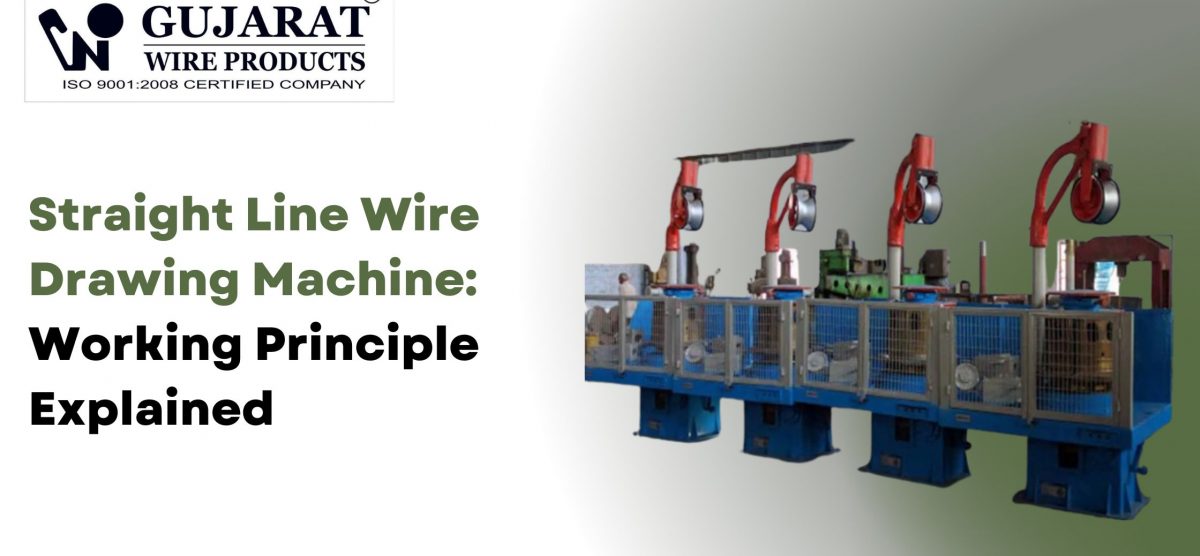

Straight Line Wire Drawing Machine: Working Principle Explained

Efficient, high-quality wire production is foundational to sectors ranging from construction to automotive, power transmission, and advanced manufacturing. Among the cutting-edge technologies revolutionizing this field, the straight line wire drawing machine stands out for its ability to deliver precision, speed, and unbeatable consistency. Gujarat Wire Products, a leader in India’s wire machinery industry, brings deep expertise and advanced engineering know-how to every machine, helping businesses unlock the full potential of straight line wire drawing.

What is a Straight Line Wire Drawing Machine?

A straight line wire drawing machine is an automated device designed to reduce the diameter of metal wires by pulling them through a series of drawing dies in a linear arrangement. Unlike traditional looping or tank-based systems, straight line machines keep the wire path rigid and direct, minimizing twisting, bending, and deviation. This architecture leads to:

- Improved product straightness

- Higher drawing speeds

- Superior surface finish

- Consistent mechanical properties

These machines are widely used for processing spring wire, steel rope wire, welding wire, prestressed concrete wire, tire bead wire, and high/medium/low carbon steel wires—catering to an array of industrial applications.

Main Components of a Straight Line Wire Drawing Machine

Understanding the core makeup of these machines is key to grasping their operation and advantages:

| Component | Role/Function |

| Pay-off Reel | Holds & unwinds the raw wire coil for feeding |

| Multiple Draw Heads | Sequentially reduce the wire diameter via dies |

| Drawing Dies | Carbide/tungsten/diamond inserts where actual wire reduction occurs |

| Capstans/Drums | Pull and guide wire under controlled tension |

| Tension Sensors | Measure wire tension between each draw head for feedback |

| Motor/Drive Units | Provide variable speed, precise torque for each capstan |

| Electrical Control Panel | Houses PLC, HMI (touchscreen), and frequency inverters |

| Take-up/Reel Unit | Automatically recoils the finished wire |

The Working Principle: Step-by-Step

1. Wire Feeding and Initial Straightening

Raw wire is mounted on the pay-off reel and fed into the first die. Entry guides often straighten the wire, eliminating bends or kinks and ensuring smooth feeding.

2. Sequential Drawing through Multiple Heads

The wire is then pulled through a series of drawing dies, each one reducing its diameter. These draws are arranged in a straight line, with each die and capstan pair forming a “draw head.” As the wire progresses:

- Each draw head operates at a slightly different speed, in proportion to the reduction at that stage.

- The mechanical drive and electronic controls ensure coordinated movement.

3. Precise Tension Control for Quality Output

One of the hallmark features of a modern straight line wire drawing machine is constant tension control. Tension sensors are placed between each draw head to detect fluctuations in the wire—such as those caused by diameter changes, speed variations, or irregular loads.

- Real-time feedback is sent to the PLC or digital controller.

- These controllers instantly adjust the speed of each capstan using Variable Frequency Drives (VFDs) and closed-loop PID (Proportional–Integral–Derivative) control processes.

- This ensures each section of wire is drawn under uniform tension, avoiding breaks and producing wires with consistent mechanical properties and a flawless surface.

4. Digital Automation for Seamless Synchronization

Thanks to digital or fieldbus communication, the machine’s HMIs and controllers continuously coordinate speeds, torques, and tension. Operators can monitor the full process via touchscreens, adjusting recipes and settings for different wire materials, diameters, or product requirements.

5. Finished Wire Take-Up

After being drawn to the final diameter, the wire is spooled onto a take-up unit or cut to length. Finished wire is now ready for use or further processing, boasting uniformity and minimal deviation from start to end.

Key Features and Advantages of Gujarat Wire Products’ Straight Line Wire Drawing Machines

1. High Precision and Speed

- Supports wire diameters from as large as Φ14mm down to very fine gauges.

- Operation speeds of up to 25 m/s for some models, maintaining consistent quality at high output rates.

2. Versatility Across Materials

- Suitable for spring steel wire, rope wire, medical wire, welding wire, aluminum-clad wire, and more.

- Handles low, medium, and high carbon wires—making it the machine of choice for varied industries.

3. Energy-Efficient Drives and Reduced Costs

- Intelligent VFD systems reduce electricity consumption, contributing to lower operation costs and better eco-compliance.

- Optimized design cuts down mechanical losses, heat, and wear.

4. Superior Wire Quality

- Constant tension means wires are produced with minimal residual stress.

- Smooth, bright surfaces and accurate diameters directly from the machine—reducing need for downstream finishing.

5. Advanced Safety and Operator Convenience

- Emergency stops, automatic alarms, and real-time fault diagnostics.

- Ergonomic layout and easy-access controls streamline both production and maintenance.

6. Digital Control and Industry 4.0 Integration

- Data logging and remote monitoring ready—supporting traceability, predictive maintenance, and smart factory environments.

- Easy recipe switching for production flexibility.

Applications of Straight Line Wire Drawing Machines

- Construction: Prestressed concrete wire, reinforcement wire

- Automotive: Tire bead wire, spring steel wire, control cables

- Electrical: Welding wire, conductor wire

- Textile: Fine wires for mesh and woven fabrics

- Medical: Precision stainless and alloy wires for surgical or dental use

Comparison: Straight Line vs. Traditional Wire Drawing Machines

| Feature | Straight Line Drawing Machine | Traditional (Loop/ Tank) Systems |

| Wire Path | Rigid, straight | Looping, may cause bends & twists |

| Speed | High, constant | Moderate, variable |

| Tension Control | Real-time, electronically managed | Manual or less precise |

| Energy Efficiency | Optimized, VFD-driven | Typically higher consumption |

| Surface Quality | Consistently smooth | More prone to marks, irregularities |

| Maintenance | Lower, modular design | Higher, more moving parts |

Maintenance and Best Practices

To keep your straight line wire drawing machine operating at peak efficiency:

- Daily: Clean the dies, check rollers/capstans for debris.

- Weekly: Inspect tension sensors and electronic connections.

- Monthly: Lubricate moving parts and check calibration of sensors.

- Annually: Have a certified technician perform a full-system check, focusing on the drive system, VFD/PID controllers, and mechanical alignment.

Frequently Asked Questions

Q: Can the same machine handle multiple wire grades and diameters?

A: Yes. With quick die change systems and programmable controls, these machines shift smoothly between different wire sizes and types.

Q: What about wire breaks or diameter inconsistencies?

A: Advanced models utilize continuous feedback and fault alarms. Optimal tension control drastically reduces the chances of breaks or off-spec wire.

Q: How long is machine setup for a new product batch?

A: Changeover is fast—often within 30–60 minutes—due to digital controls and user-friendly interfaces.

Q: Are these machines suitable for export-quality or high-precision wire?

A: Absolutely. They are widely adopted by exporters for industries demanding rigorous tolerances, shiny finishes, and uniformity.

Why Choose Gujarat Wire Products for Your Wire Drawing Solution?

- Cutting-edge technology: Industry-leading automation, VFD drive systems, and sensor controls.

- Experience you can trust: Decades of innovation, technical support, and customization expertise.

- Comprehensive support: Installation, operator training, rapid spares, and technical service—pan India and global.

- Proven results: Success stories across construction, automotive, electrical, and specialty wire sectors.

Conclusion: The New Standard in Wire Drawing—Precision, Efficiency, and Reliability

Straight line wire drawing machines are the bedrock of modern, efficient wire manufacturing—blending robust mechanical design with the latest in automation and digital monitoring. Businesses who invest in advanced solutions from Gujarat Wire Products position themselves for quality leadership, productivity gains, and a future-ready factory.

Streamline your wire production. Elevate your business. Choose Gujarat Wire Products for the industry’s best straight line wire drawing machines.