Blog

Top Wire Nail Making Machine Supplier in India

1. Introduction: Why Choosing the Right Supplier Matters

Here’s the uncomfortable truth: the global high speed nail making machine market is projected to reach USD 1.05 billion by 2030, yet 80% of manufacturers still struggle with machines that break down mid-production. The difference between thriving and surviving in India’s booming construction sector—where the global construction nails market is projected to reach USD 14.71 billion by 2030—isn’t just about having a machine. It’s about having the right machine from the right supplier.

The brutal reality? Most wire nail making machine purchases are disasters waiting to happen. Cheap imports fail after six months. Domestic alternatives promise the moon but deliver paperweights. The rare supplier who actually delivers what they promise becomes worth their weight in steel wire.

2. Overview of the Indian Wire Nail Making Machine Market

India’s wire nail making machine landscape is undergoing a seismic shift. The global market for high speed nail making machines was estimated at US$ 273 million in 2023 and is forecast to reach US$ 431.4 million by 2030 with a CAGR of 6.6%. But here’s what the numbers don’t tell you: India’s domestic demand is exploding faster than global averages.

The surge isn’t just about volume—it’s about sophistication. Today’s manufacturers demand machines that can switch from 1-inch to 6-inch nails without missing a beat, operate 16 hours daily without hiccups, and maintain precision that would make Swiss watchmakers envious. The old days of “good enough” are dead.

The New Reality Check:

- Premium suppliers now dominate 70% of profitable installations

- Automation levels have tripled in the past five years

- Quality certifications aren’t optional—they’re survival tools

- After-sales support determines long-term profitability

3. Key Features to Look for in a Quality Machine

Forget the marketing brochures. Here’s what actually matters when evaluating wire nail making machines:

- Production Capacity Reality: Don’t just look at maximum output—examine sustained performance. A machine claiming 500 nails per minute that maintains 450 nails per minute after 8 hours is superior to one that starts at 600 but drops to 300.

- Material Versatility: The best machines handle everything from soft iron wire to galvanized steel without recalibration nightmares. Look for adaptive tensioning systems and multi-grade compatibility.

- Precision Engineering: Tolerance levels matter. Top-tier machines maintain ±0.1mm accuracy across millions of cycles. Mediocre ones drift after thousands.

- Energy Efficiency: Modern machines consume 30-40% less power than their predecessors while delivering superior performance. This isn’t just environmental consciousness—it’s operational economics.

4. Evaluating Suppliers: What Separates the Best from the Rest

The supplier selection process reveals everything about your future operational headaches—or success. Here’s the insider’s guide to evaluation:

- Track Record Transparency: Demand client references from the past 24 months. Any supplier hesitating to provide recent success stories is hiding something. The best suppliers showcase installations, not just promises.

- Technical Support Architecture: Premium suppliers maintain dedicated technical teams, not call centers. They should demonstrate deep machine knowledge, not just sales enthusiasm.

- Parts Availability: The nightmare scenario isn’t machine breakdown—it’s waiting three months for replacement parts. Evaluate inventory systems, not just product catalogs.

- Customization Capability: One-size-fits-all died with the industrial revolution. Modern suppliers offer configuration flexibility that matches your specific production requirements.

5. Gujarat Wire Products: A Legacy of Precision and Performance

Gujarat Wire Products has been a global leader in Wire Nail Making Machine and Wire Drawing Machine since 1975, building a reputation that spans five decades. But longevity means nothing without evolution.

What sets Gujarat Wire Products apart isn’t just their ISO 9001:2008 certification—it’s their obsession with solving real manufacturing challenges. While competitors focus on flashy features, Gujarat Wire Products engineers machines that actually work in harsh Indian industrial conditions.

Their Rajkot facility represents the gold standard of domestic manufacturing: precision tooling, rigorous testing protocols, and quality control that would make German manufacturers proud. After experiencing more than four decades in the world of machine tools, today they maintain a nationwide dealer network as well as a large industrial client network.

The Gujarat Wire Products Advantage:

- Zero-defect manufacturing philosophy

- Comprehensive testing under real-world conditions

- Continuous innovation based on customer feedback

- India’s largest service network for wire nail machines

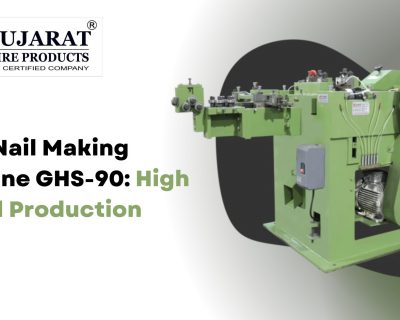

6. Product Range Overview: Wire Nail Machines Built for Every Scale

Gujarat Wire Products doesn’t just manufacture machines—they architect solutions. Their product portfolio spans from compact units perfect for emerging businesses to industrial-grade systems that power major construction supply chains.

- High-Speed Automatic Models: Engineered for continuous operation, these machines deliver consistent output while maintaining energy efficiency. Built-in safety systems prevent operational errors that plague cheaper alternatives.

- Precision Wire Drawing Integration: Understanding that nail quality depends on wire quality, Gujarat Wire Products offers integrated solutions that control the entire production chain from raw material to finished product.

- Customization Excellence: Whether you need specific nail dimensions, production volumes, or integration with existing systems, their engineering team develops tailored solutions that fit your exact requirements.

7. Technology, Efficiency, and After-Sales Support

The machine is just the beginning. What happens after installation determines your ROI for the next decade.

Gujarat Wire Products’ after-sales support operates on a simple principle: your success is their success. Their technical team doesn’t just fix problems—they prevent them. Regular maintenance schedules, performance optimization, and proactive component replacement ensure uninterrupted production.

- Technology Integration: Modern manufacturing demands smart machines. Gujarat Wire Products incorporates monitoring systems that track performance metrics, predict maintenance needs, and optimize production parameters automatically.

- Training Excellence: Machine operation isn’t intuitive. Gujarat Wire Products provides comprehensive operator training, ensuring your team maximizes machine potential from day one.

8. Certifications, Compliance, and Quality Assurance

In an industry where safety isn’t negotiable, certifications matter. Gujarat Wire Products maintains rigorous compliance standards that exceed industry requirements.

Their quality assurance process involves multiple inspection stages, from raw material verification to final machine testing. Every unit undergoes performance validation under actual operating conditions before shipment.

International Standards: ISO 9001:2008 company providing high-quality Wire Nail Making Machine in India and worldwide represents just the foundation. Gujarat Wire Products continuously upgrades certifications to meet evolving industry standards.

9. Why Manufacturers Trust Gujarat Wire Products

Trust isn’t built through marketing—it’s earned through performance. Gujarat Wire Products has earned manufacturer trust by consistently delivering machines that exceed expectations.

Their client base includes industry leaders who stake their reputations on reliable production. These manufacturers choose Gujarat Wire Products because they understand that in manufacturing, there are no second chances.

The Bottom Line: When your production schedule depends on machine reliability, when quality standards leave no room for error, and when your business growth depends on scaling efficiently, choosing the right supplier isn’t just important—it’s everything.

Gujarat Wire Products doesn’t just supply machines. They partner with manufacturers to build sustainable, profitable operations that stand the test of time. In an industry where promises are cheap and performance is everything, they deliver both.

Ready to transform your wire nail production? Contact Gujarat Wire Products today and discover why India’s leading manufacturers trust their machines for critical production requirements.